Superalloy Cemet Vapor Chamber

Product Information

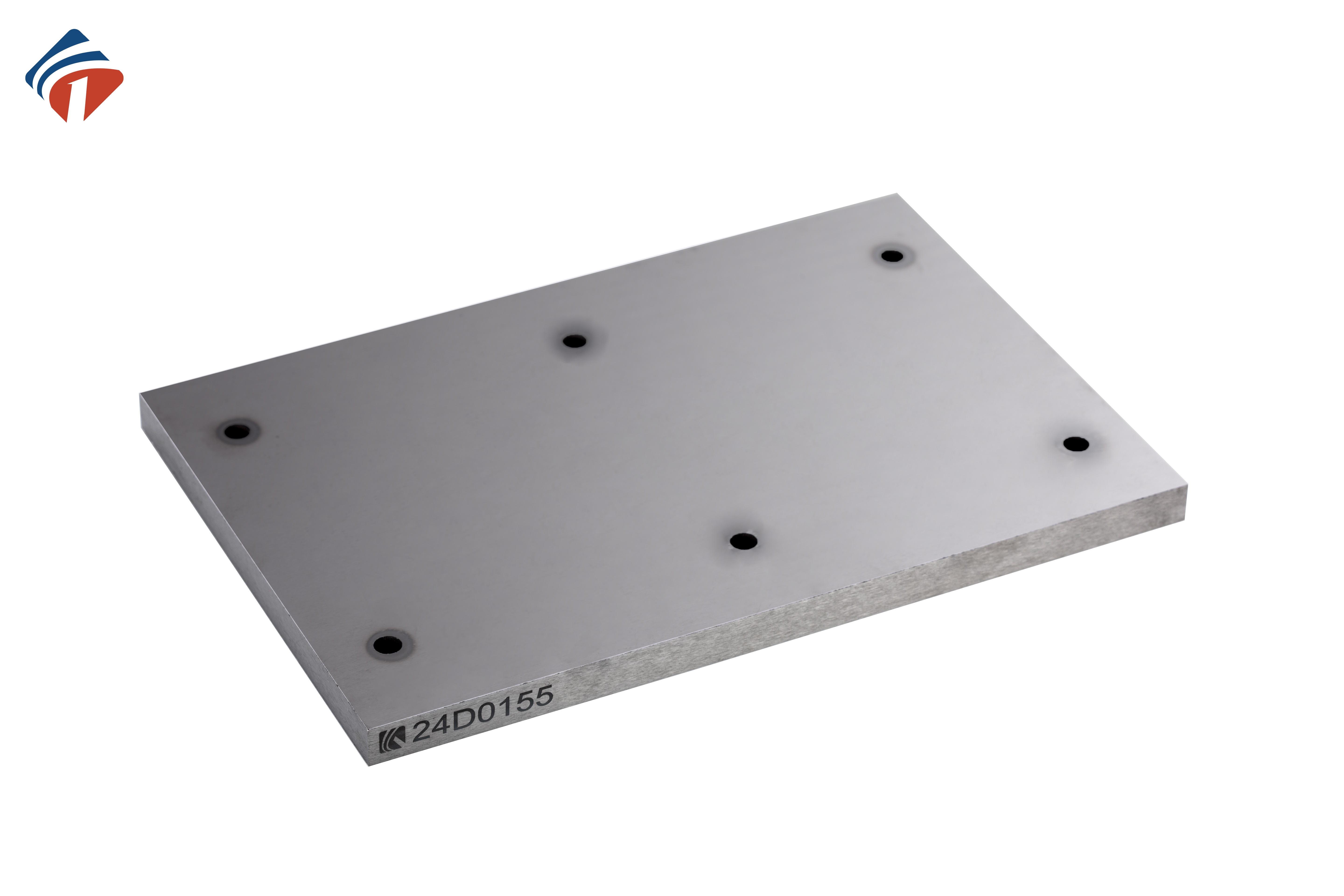

Product Name: Superalloy Cemet Vapor Chamber

- Material: cermet, tungsten carbide, and binder.

- Application apparatus: 3D curved glass hot bending machine 、Precision molding machine for freeform surfaces (HUD)

- Machinable workpiece: 3D curved glass, Automotive HUD screens, LiDAR windows, Camera lens

- Advantage:

1)Moderate coefficient of thermal expansion, high compatibility with heating plates, and no deformation under high temperatures or temperature variations.

2)High-temperature strength, capable of withstanding loads at temperatures up to 950°C without deformation.

3)High thermal conductivity, enabling uniform and rapid heat transfer.

4)High specific heat capacity, excellent temperature stability.

5) High hardness, low friction coefficient, long service life.

6) Strong high-temperature oxidation resistance, no anti-oxidation coating needed.

Description

Technical Parameter

The heat distribution plate is a key component in the glass hot bending and pressing production process, mainly used to evenly transfer heat to the mold plate under high-temperature conditions, ensuring that the glass evenly distributes the temperature of the heating plate on the forming mold during the hot bending process, and providing the pressure required for hot bending forming, thereby ensuring the quality of the hot-bent glass.

Application Scenarios: The formed glass is mainly used in the 3C industry and the automotive industry, as 3D curved screens and back covers for mobile phones, front and back cover plates for laptops, smartwatches, Vision Pro and other intelligent wearable devices, as well as AR-HUD reflectors and other high-end products. These products have extremely high requirements for the shape precision, surface quality, and optical performance of the glass.

Tianyi's superalloy metal ceramic heat distribution plate is an important tool to help glass manufacturers solve these issues.

Advantages Description

Comparison with similar products of different materials:

1. Flatness deformation is less than 0.007mm

2. High oxidation resistance—no coating required.

3. Service life is ≥12 months.

The superalloy metal ceramic material plate is your best choice.

The precision of temperature and pressure control during the hot bending process determines the final shape and surface quality of the product.

Tianyi Superalloy Metal Ceramic Plate is a newly developed material specifically for high-temperature forming operations in 3D glass bending machines, aspherical precision press machines, and freeform (HUD) glass precision press machines.

Compared to traditional tungsten steel plates, Tianyi plates have higher hardness and excellent high-temperature oxidation resistance. Under high-temperature pressing conditions, they have minimal temperature deviation, more uniform heat conduction, and only slight deformation (<0.007mm), significantly extending their service life. They are particularly suitable for processing microcrystalline glass at 900 degrees during hot bending operations.

INQUIRY

Related product categories

- carbide roll rings for steel industry

- wear-resistant rolls for seamless tube mills

- cemented carbide roll ring manufacturers for seamless tube mills

- best carbide roll rings for bar mills

- buy carbide roll rings for hot rolling

- comparison of carbide roll rings and steel roll rings for wire rod mills

- cemented carbide tool for drilling

- cemented carbide turning tool for aerospace parts

- custom size roll rings Poland

- cemented carbide end mill cutters

- carbide cnc end mill

- cemented carbide rods blanks

EN

EN UR

UR ru

ru bn

bn ar

ar ky

ky th

th fil

fil vi

vi ms

ms tr

tr ro

ro pt

pt es

es af

af fa

fa uk

uk nl

nl pl

pl fr

fr de

de