Manufacturing process of cemented carbide

The main raw materials used in cemented carbide production include tungsten trioxide, tungsten powder, titanium dioxide, tantalum (niobium) powder or tantalum (niobium) pentoxide, cobalt oxide (or cobalt powder), carbon black, etc. During the production process, raw materials such as tungsten carbide, titanium carbide, tantalum carbide, niobium carbide, and metallic cobalt powder are typically required.

Production Process of Cemented Carbide Flow:

Raw material mixing → Carburization → Ball milling → Wet milling → Filtration → Drying → Sieving → Blending → Drying → Grinding → Wire drawing → Pressing → Drying → Machining → Semi-inspection → Loading → Sintering → Sandblasting → Final inspection → Packaging

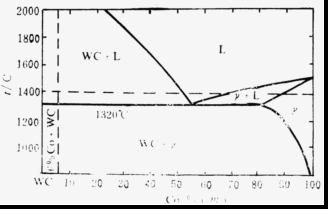

In the above process, sintering is one of the crucial steps in the production of powder metallurgy products. Its purpose is to strengthen the product to achieve the final required physical and mechanical properties. The sintering of cemented carbide is a typical liquid-phase sintering process, which can be divided into three stages:

1. Below 1000°C.

2. 1000°C to sintering temperature** – the most critical stage.

3. Cooling stage.

Related product categories

- tungsten carbide rolls for hot rolling

- reduce downtime with carbide rolls for high-temperature applications

- small carbide roll rings for steel mills

- custom-manufactured roll rings for hot strip mills

- tungsten carbide roll ring suppliers for wire rod production

- OEM carbide roll rings for steel industry

- improve rolling mill efficiency Saudi Arabia

- China carbide roll rings Canada

- cemented carbide rolls Turkey Germany

- china end mill tools

- tool cutting

- china custom tungsten rod

EN

EN UR

UR ru

ru bn

bn ar

ar ky

ky th

th fil

fil vi

vi ms

ms tr

tr ro

ro pt

pt es

es af

af fa

fa uk

uk nl

nl pl

pl fr

fr de

de