Boron Nitride Ceramic Material Molding Molds

Material: Boron Nitride Ceramic (BN)

Specifications: Customizable according to customer requirements

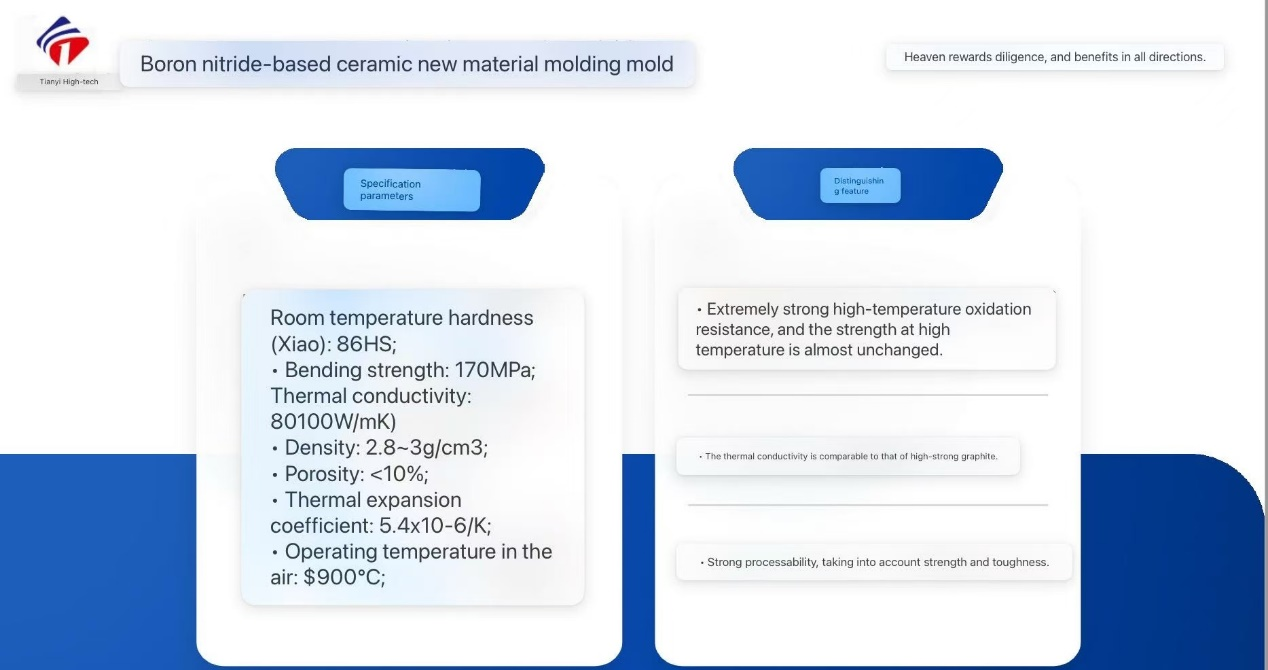

Specifications and Parameters:

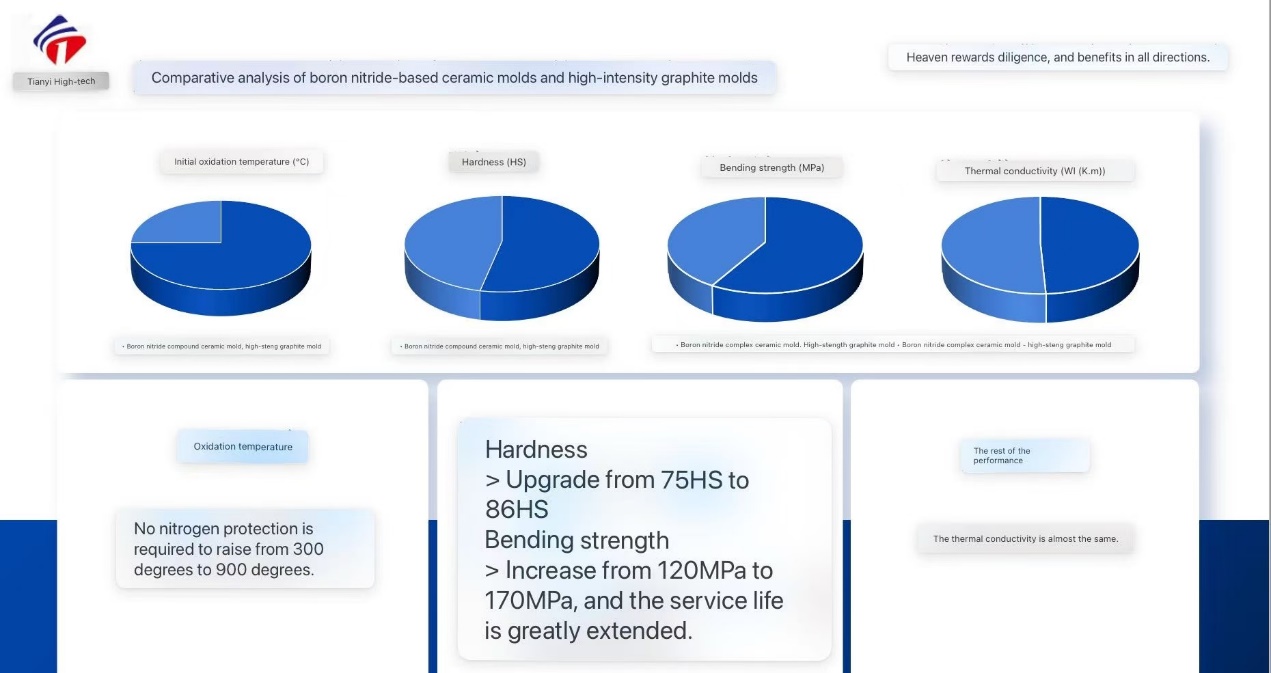

· Room Temperature Hardness (Shore): 86HS

· Bending Strength: 170 MPa

· Thermal Conductivity: 80-100 W/mK

· Density: 2.8~3 g/cm³

· Porosity: <10%

· Coefficient of Thermal Expansion: 5.4x10⁻⁶ K

· Maximum Operating Temperature in Air: ≤900°C

Description

Product Features:

· Exceptional resistance to high-temperature oxidation, with strength almost unchanged at high temperatures.

· Thermal conductivity comparable to high-strength graphite.

· Strong machinability, balancing both strength and toughness.

· The material exhibits excellent thermal stability, wear resistance, and chemical inertness.

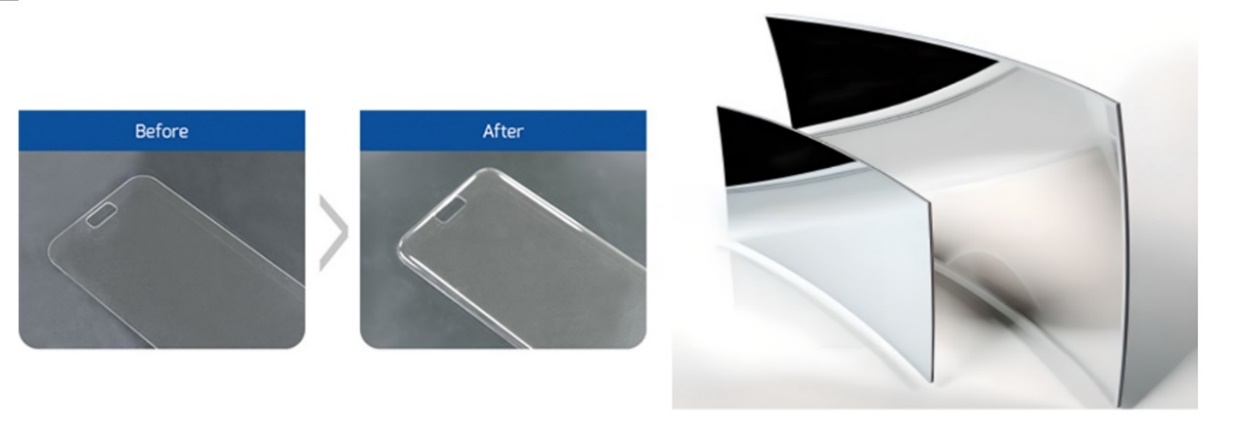

· Its high-temperature resistance and excellent thermal conductivity make it an ideal material for glass bending machine molds and smartphone screen forming molds.

· Boron Nitride Ceramic Molds A Replacement for High-strength Graphite

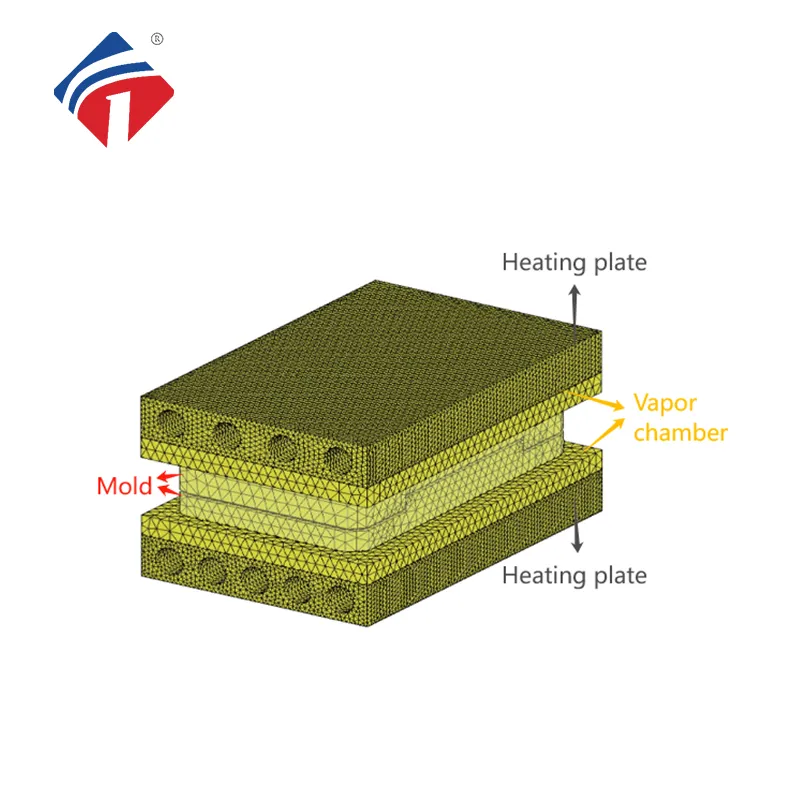

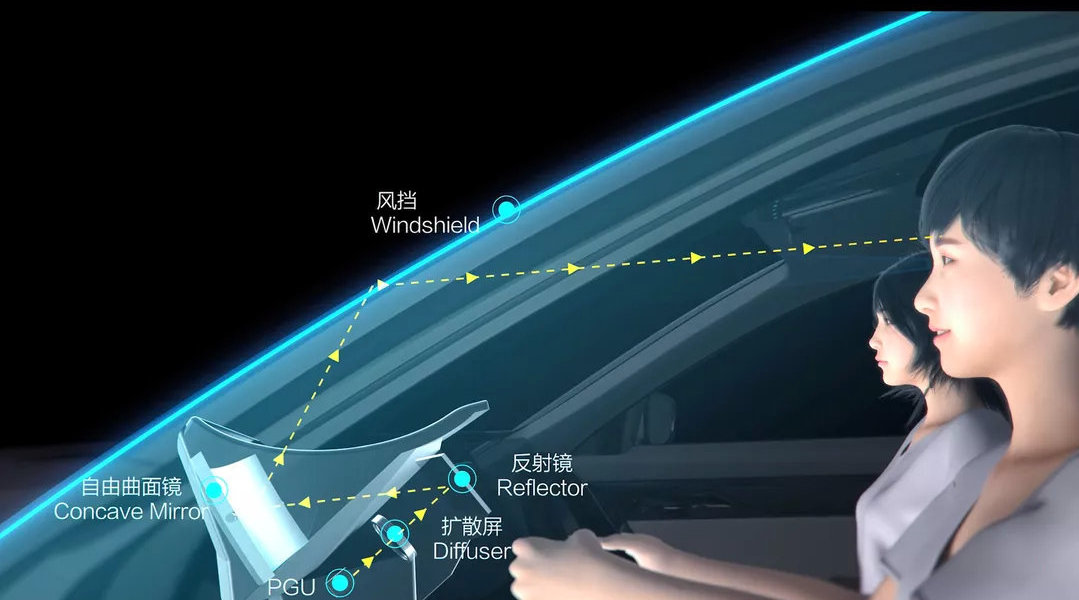

Application Scenarios and Uses: Mainly used in non-spherical/free-form (HUD) precision molding machines, 3D glass bending machines, and other related equipment.

The processing method involves placing flat glass substrates in molds, heating the equipment to soften the glass, and then forming it according to the precise curved shape of the mold cavity. Finally, the formed glass undergoes annealing and cooling to produce curved glass products such as smartphone screens, laptop screens and back covers, automotive central control screens, in-car HUD displays, AR-HUD mirrors, etc.

INQUIRY

Related product categories

- OEM carbide roll rings for special steel manufacturing

- carbide rolls for reversing mills

- carbide roll rings for wire rod mills

- China carbide roll rings for special steel manufacturing

- carbide roll ring maintenance for rolling mills

- wear-resistant rolls for cold rolling

- tungsten carbide roll rings Indonesia

- kocks cemented carbide roll rings for metal cutting

- benefits of using cemented carbide roll rings Pakistan

- drilling bits cemented carbide

- cemented carbide tool

- china steel end mill

EN

EN UR

UR ru

ru bn

bn ar

ar ky

ky th

th fil

fil vi

vi ms

ms tr

tr ro

ro pt

pt es

es af

af fa

fa uk

uk nl

nl pl

pl fr

fr de

de