Description

End mill working condition calculation method

|

●Cutting speed (linear speed) Calculation VC The distance that a point on the circumference of the end mill blade moves per minute can be calculated using the following formula: |

|

|

V=Cutting speed(m/min) π=3.14 D=Diameter(mm) N=Rotating speed(mm-¹) |

|

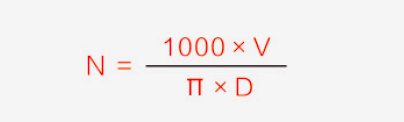

●Rotation speed Calculation of Rotationspeed The number of revolutions per minute of the mechanical spindle that holds the end mill can be calculated using the following formula: |

|

|

N=Rotating speed(mm-¹) V=Cutting speed(m/min) π=3.14 D=Diameter(mm) |

|

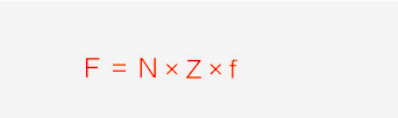

● Feed rate Calculation of Feed rate The feed speed of the worktable per minute can be calculated by the following formula  F=Feed rate(mm/min) N=Rotating speed(mm-1) Z=Number of flute f=Feed rate of the flute(mm/1flute) |

|

|

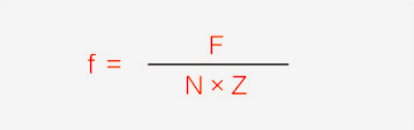

● Feed for teeth Calculation of the Feed ofteeth The distance that a point on the circumference of the end mill blade moves per minute can be calculated using the following formula:  f=Feed rate of the flute(mm/1flute) F=Feed rate(mm/min) N=Rotating speed(mm-1) Z=Number of flute |

|

|

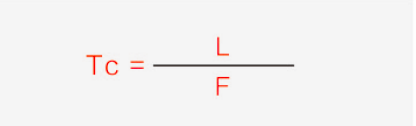

●Working time Calculation of the Working time The time required to cut the workpiece material can be calculated using the following formula  Tc=Working time(min) L=Total working length (Working material length + end mill blade diameterD) F=Feed rate(mm/min) |

|

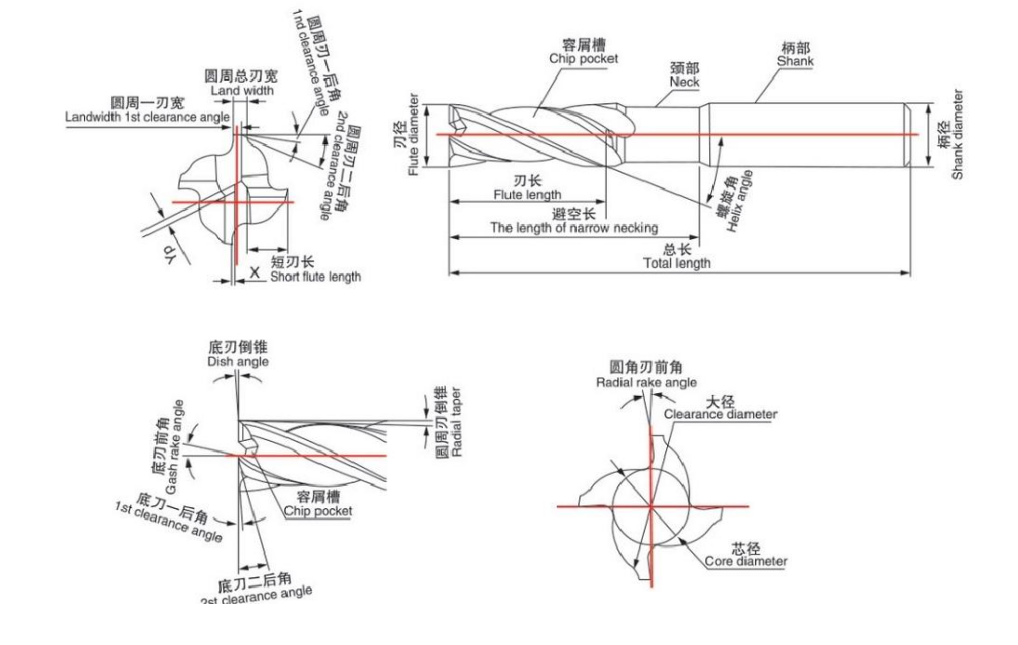

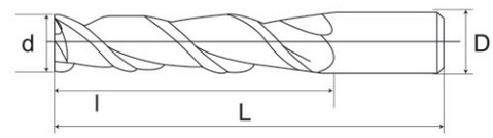

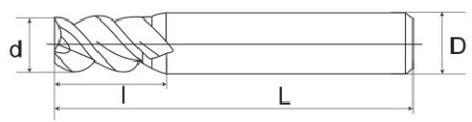

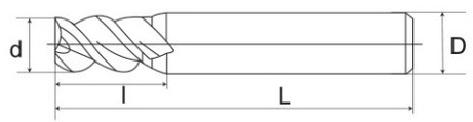

Name of each part of the milling cutter

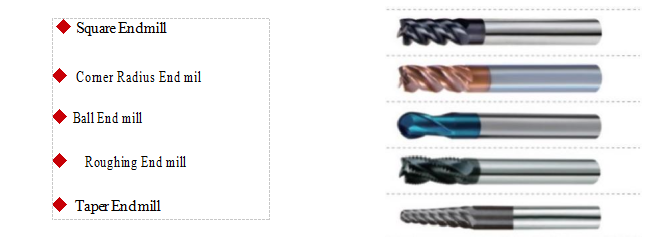

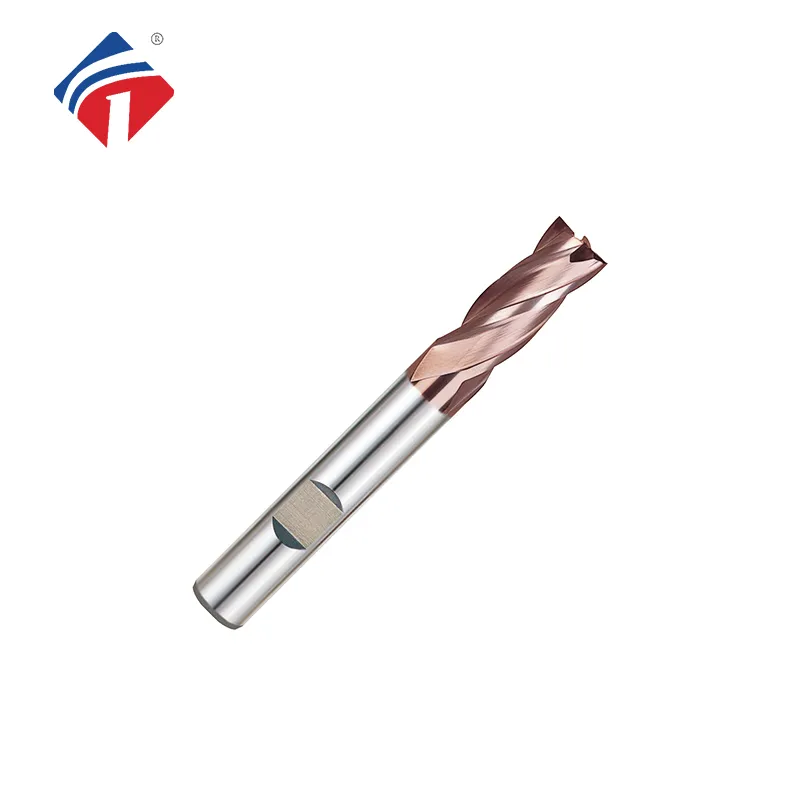

Milling cutter series

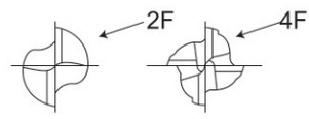

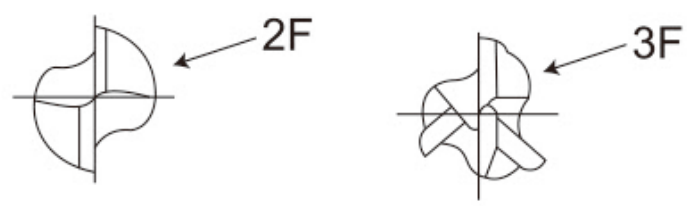

End mill type End mill shape

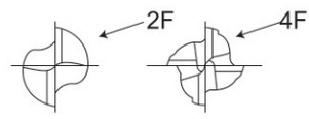

2-flute/4-flute end mills

WC=90/88 Co=10/12 HV30=1571 TRS=3750N/mm² HRC≥91.5 Grain Size=0.6μm

|

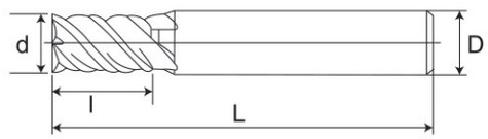

d |

I |

L |

D |

F |

|

1 |

3 |

50 |

4 |

2/4 |

|

1.5 |

4 |

50 |

4 |

2/4 |

|

2 |

5 |

50 |

4 |

2/4 |

|

2.5 |

6 |

50 |

4 |

2/4 |

|

3 |

7 |

50 |

4 |

2/4 |

|

3.5 |

8 |

50 |

4 |

2/4 |

|

4 |

10 |

50 |

4 |

2/4 |

|

5 |

13 |

50 |

6 |

2/4 |

|

6 |

15 |

50 |

6 |

2/4 |

|

7 |

18 |

60 |

8 |

2/4 |

|

8 |

20 |

60 |

8 |

2/4 |

|

10 |

25 |

75 |

10 |

2/4 |

|

12 |

30 |

75 |

12 |

2/4 |

|

14 |

45 |

100 |

14 |

2/4 |

|

16 |

45 |

100 |

16 |

2/4 |

|

18 |

45 |

100 |

18 |

2/4 |

|

20 |

45 |

100 |

20 |

2/4 |

2-Flute/4-Flute extended end mill

WC=90/88 Co=10/12 HV30=1571 TRS=3750N/mm² HRC≥91.5 Grain Size=0.6 μm

|

d |

I |

L |

D |

F |

|

4 |

15 |

100 |

4 |

2/4 |

|

|

25 |

100 |

6 |

2/4 |

|

8 |

30 |

100 |

8 |

2/4 |

|

10 |

40 |

100 |

8 |

2/4 |

|

12 |

45 |

100 |

10 |

2/4 |

|

8 |

40 |

150 |

10 |

2/4 |

|

10 |

50 |

150 |

12 |

2/4 |

|

12 |

60 |

150 |

12 |

2/4 |

|

14 |

65 |

150 |

14 |

2/4 |

|

16 |

70 |

150 |

16 |

2/4 |

|

18 |

70 |

150 |

18 |

2/4 |

|

20 |

70 |

150 |

20 |

2/4 |

◆Special Attention:

1. This table is the standard value for side milling. When the tool is grooving, the speed should be 60%~80% of the table below, and the feed speed should be 50%~70% as the standard value.

2. Please use high-precision machine tools and tool holders.

3. Please use air cooling or cutting fluid that does not easily produce smoke.

4. Side milling is recommended for down milling.

5. If the rigidity of the machine tool and the workpiece is poor, vibration and abnormal sound will occur. At this time, the speed and feed speed in the table below should be reduced year by year.

6. Keep the tool overhang as short as possible without interference.

Cutting conditions

|

2 Flute |

|||||||||||||||

|

Processed materials |

Cast iron Ductile iron |

Carbon steel\alloy steel |

Carbon steel\alloy steel ~30HRC |

PHS\QT Steel~40HRC |

Stainless steel |

PHS\QT Steel ~50HRC |

|||||||||

|

Dia (mm) |

RPM(min-) |

Feedrate (mm/min) |

RPM (min-¹) |

Feedrate (mm/min) |

RPM (min-) |

Feedrate (mm/min) |

RPM (min-¹) |

Feedrate (mm/min) |

RPM (min-¹) |

Feedrate (mm/min) |

RPM (min-¹) |

Feedrate (mm/min) |

|||

|

1 |

20000 |

165 |

20000 |

165 |

20000 |

135 |

20000 |

135 |

20000 |

50 |

20000 |

100 |

|||

|

2 |

15000 |

265 |

15000 |

265 |

15000 |

240 |

15000 |

235 |

11150 |

70 |

13000 |

150 |

|||

|

3 |

14000 |

455 |

14000 |

455 |

13000 |

420 |

10600 |

350 |

7500 |

100 |

8500 |

275 |

|||

|

4 |

10800 |

465 |

10800 |

465 |

10000 |

430 |

8000 |

355 |

5500 |

110 |

6500 |

280 |

|||

|

5 |

8200 |

485 |

8200 |

485 |

7600 |

450 |

6400 |

370 |

4500 |

110 |

5000 |

295 |

|||

|

6 |

7000 |

500 |

7000 |

500 |

6400 |

460 |

5300 |

385 |

3700 |

115 |

4200 |

300 |

|||

|

8 |

5200 |

495 |

5200 |

495 |

4800 |

455 |

4000 |

380 |

2800 |

115 |

3200 |

305 |

|||

|

10 |

4200 |

485 |

4200 |

485 |

3800 |

450 |

3200 |

370 |

2200 |

115 |

2500 |

290 |

|||

|

12 |

3500 |

485 |

3500 |

485 |

3200 |

450 |

2650 |

370 |

1850 |

115 |

2100 |

290 |

|||

|

14 |

3000 |

455 |

3000 |

455 |

2700 |

420 |

2300 |

350 |

1600 |

110 |

1800 |

275 |

|||

|

16 |

2600 |

455 |

2600 |

455 |

2400 |

420 |

2000 |

350 |

1400 |

100 |

1600 |

275 |

|||

|

18 |

2300 |

445 |

2300 |

445 |

2100 |

410 |

1800 |

345 |

1250 |

100 |

1400 |

270 |

|||

|

20 |

2050 |

445 |

2050 |

445 |

1900 |

410 |

1600 |

345 |

1100 |

100 |

1250 |

270 |

|||

|

4 Flute |

|||||||||||||||

|

1 |

20000 |

250 |

20000 |

250 |

20000 |

200 |

20000 |

200 |

20000 |

90 |

20000 |

150 |

|||

|

2 |

15000 |

400 |

15000 |

400 |

15000 |

360 |

15000 |

350 |

11150 |

100 |

13000 |

225 |

|||

|

3 |

14000 |

680 |

14000 |

680 |

13000 |

630 |

10600 |

525 |

7500 |

120 |

8500 |

410 |

|||

|

4 |

10800 |

700 |

10800 |

700 |

10000 |

640 |

8000 |

535 |

5500 |

125 |

6500 |

420 |

|||

|

5 |

8200 |

730 |

8200 |

730 |

7600 |

670 |

6400 |

560 |

4500 |

125 |

5000 |

440 |

|||

|

6 |

7000 |

750 |

7000 |

750 |

6400 |

690 |

5300 |

575 |

3700 |

135 |

4200 |

450 |

|||

|

8 |

5200 |

740 |

5200 |

740 |

4800 |

680 |

4000 |

565 |

2800 |

135 |

3200 |

460 |

|||

|

10 |

4200 |

730 |

4200 |

730 |

3800 |

670 |

3200 |

560 |

2200 |

135 |

2500 |

435 |

|||

|

12 |

3500 |

730 |

3500 |

730 |

3200 |

670 |

2650 |

560 |

1850 |

135 |

2100 |

435 |

|||

|

14 |

3000 |

680 |

3000 |

680 |

2700 |

630 |

2300 |

525 |

1600 |

125 |

1800 |

410 |

|||

|

16 |

2600 |

680 |

2600 |

680 |

2400 |

630 |

2000 |

525 |

1400 |

120 |

1600 |

410 |

|||

|

18 |

2300 |

670 |

2300 |

670 |

2100 |

620 |

1800 |

515 |

1250 |

105 |

1400 |

405 |

|||

|

20 |

2050 |

670 |

2050 |

670 |

1900 |

620 |

1600 |

515 |

1100 |

105 |

1250 |

405 |

|||

|

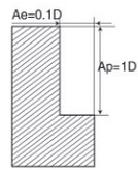

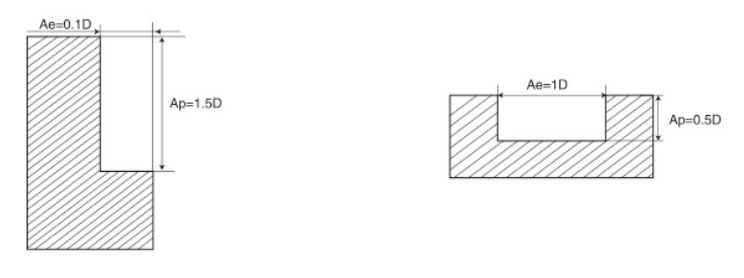

Max Cutting Depth |

Ae=0.1D Ap=1D |

Ae=0.05D |

Ae=1D Ap Ap=1D Ae=1D |

|

|||||||||||

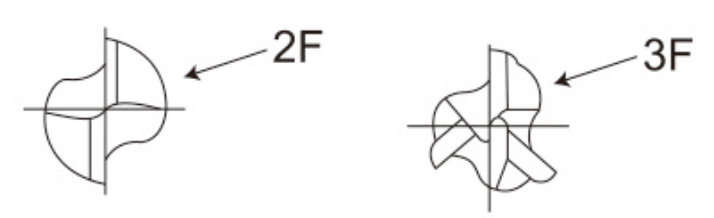

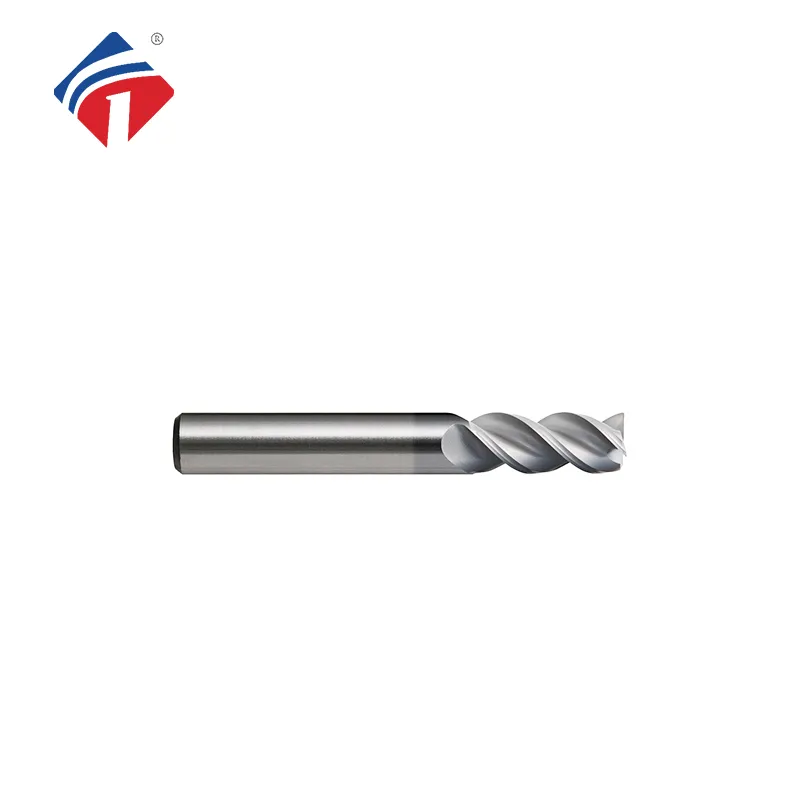

2-Flute/3-Flute end mill for aluminum alloy

WC=90/88 Co=10/12 HV30=1571 TRS=3750N/mm² HRC≥91.5Grain Size=0.6 μm

|

d |

I |

L |

D |

F |

|

1 |

3 |

50 |

4 |

2/3 |

|

1.5 |

4 |

50 |

4 |

2/3 |

|

2 |

6 |

50 |

4 |

2/3 |

|

2.5 |

8 |

50 |

4 |

2/3 |

|

3 |

9 |

50 |

4 |

2/3 |

|

3.5 |

10 |

50 |

4 |

2/3 |

|

4 |

12 |

50 |

4 |

2/3 |

|

5 |

15 |

50 |

6 |

2/3 |

|

6 |

18 |

50 |

6 |

2/3 |

|

7 |

20 |

60 |

8 |

2/3 |

|

8 |

24 |

60 |

8 |

2/3 |

|

10 |

30 |

75 |

10 |

2/3 |

|

12 |

35 |

75 |

12 |

2/3 |

|

14 |

40 |

100 |

14 |

2/3 |

|

16 |

45 |

100 |

16 |

2/3 |

|

18 |

45 |

100 |

18 |

2/3 |

|

20 |

50 |

100 |

20 |

2/3 |

2-Flute/3-Flute Aluminum Alloy Extended Special End Mill

WC=90/88 Co=10/12 HV30=1571 TRS=3750N/mm² HRC≥91.5 Grain Size=0.6μm

|

d |

I |

L |

D |

F |

|

4 |

16 |

100 |

4 |

2/3 |

|

6 |

25 |

100 |

6 |

2/3 |

|

8 |

32 |

100 |

8 |

2/3 |

|

10 |

40 |

100 |

10 |

2/3 |

|

12 |

45 |

100 |

12 |

2/3 |

|

8 |

40 |

150 |

8 |

2/3 |

|

10 |

50 |

150 |

10 |

2/3 |

|

12 |

60 |

150 |

12 |

2/3 |

|

14 |

65 |

150 |

14 |

2/3 |

|

16 |

65 |

150 |

16 |

2/3 |

|

18 |

70 |

150 |

18 |

2/3 |

|

20 |

70 |

150 |

20 |

2/3 |

◆Special Attention:

1. The following table shows the standard values for side milling. When the tool is grooving, the speed should be 60%~80% of the table below, and the feed speed should be 50%~70% as the standard value.

2. Please use high-precision machine tools and tool holders.

3. Please use air cooling or cutting fluid that does not easily produce smoke.

4. Down milling is recommended for side milling.

5. If the rigidity of the machine tool and the workpiece is poor, vibration and abnormal sound will occur. At this time, the speed and feed speed in the table below should be reduced year-on-year.

6. Keep the tool overhang as short as possible without interference.

Aluminum Cutting Conditions

|

2Flute |

||||

|

Processed materials |

Aluminum Alloy |

Silicon Aluminum Alloy Si≤10% |

||

|

D (mm) |

RPM (min-') |

Feedrate (mm/min) |

RPM (min-¹) |

Feedrate (mm/min) |

|

1 |

40000 |

650 |

40000 |

500 |

|

2 |

40000 |

950 |

32000 |

750 |

|

3 |

26500 |

1500 |

21000 |

1100 |

|

4 |

20000 |

1600 |

16000 |

1250 |

|

5 |

16000 |

1500 |

13000 |

1100 |

|

6 |

13000 |

1250 |

10600 |

1000 |

|

8 |

10000 |

1400 |

8000 |

1100 |

|

10 |

8000 |

1600 |

6500 |

1250 |

|

12 |

6600 |

1650 |

5300 |

1300 |

|

14 |

5700 |

1700 |

4600 |

1350 |

|

16 |

5000 |

1700 |

4000 |

1350 |

|

18 |

4400 |

1700 |

3500 |

1350 |

|

20 |

4000 |

1700 |

3200 |

1350 |

|

|

|

3Flute |

|

|

|

1 |

40000 |

800 |

40000 |

600 |

|

2 |

40000 |

1200 |

32000 |

900 |

|

3 |

26500 |

1800 |

21000 |

1300 |

|

4 |

20000 |

2000 |

16000 |

1500 |

|

5 |

16000 |

1750 |

13000 |

1300 |

|

6 |

13000 |

1500 |

10600 |

1200 |

|

8 |

10000 |

1650 |

8000 |

1300 |

|

10 |

8000 |

1900 |

6500 |

1500 |

|

12 |

6600 |

1950 |

5300 |

1550 |

|

14 |

5700 |

2000 |

4600 |

1600 |

|

16 |

5000 |

2000 |

4000 |

1600 |

|

18 |

4400 |

2000 |

3500 |

1600 |

|

20 |

4000 |

2000 |

3200 |

1600 |

Max Cutting Dept

|

INQUIRY

Related product categories

- china cnc end mill cutter

- china solid tungsten carbide rods manufacturers

- china cnc plastic cutting end mill

- china low end cnc mill

- china end mill router bit

- china cold milling roller

- china cemented carbide bits

- hobby cnc end mill

- china tungsten carbide roller ring

- miniature end mills

- solid carbide end mills

- cnc end mill kit

EN

EN UR

UR ru

ru bn

bn ar

ar ky

ky th

th fil

fil vi

vi ms

ms tr

tr ro

ro pt

pt es

es af

af fa

fa uk

uk nl

nl pl

pl fr

fr de

de

6

6 ~750N/mm²

~750N/mm²