Description

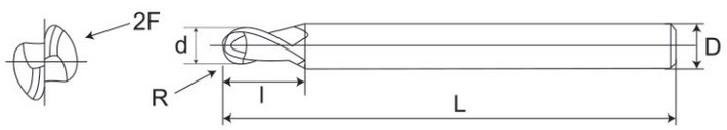

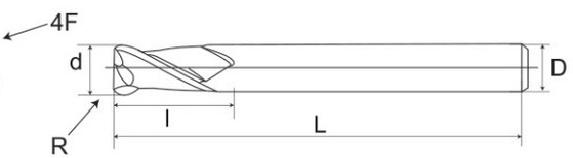

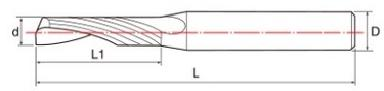

2-Flute ball end mill

WC=90/88 Co=10/12 HV30=1571 TRS=3750N/mm² HRC≥91.5 Grain Size=0.6μm

|

d |

I |

L |

D |

R |

F |

|

1 |

2 |

50 |

4 |

0.5 |

2 |

|

1.5 |

3 |

50 |

4 |

0.75 |

2 |

|

2 |

4 |

50 |

4 |

1 |

2 |

|

2.5 |

5 |

50 |

4 |

1.25 |

2 |

|

3 |

6 |

50 |

4 |

1.5 |

2 |

|

3.5 |

7 |

50 |

4 |

1.75 |

2 |

|

4 |

8 |

50 |

4 |

2 |

2 |

|

5 |

10 |

50 |

6 |

2.5 |

2 |

|

6 |

12 |

50 |

6 |

3 |

2 |

|

7 |

15 |

60 |

8 |

3.5 |

2 |

|

8 |

16 |

60 |

8 |

4 |

2 |

|

10 |

20 |

75 |

10 |

5 |

2 |

|

12 |

25 |

75 |

12 |

6 |

2 |

|

14 |

28 |

100 |

14 |

7 |

2 |

|

16 |

32 |

100 |

16 |

8 |

2 |

|

18 |

36 |

100 |

18 |

9 |

2 |

|

20 |

40 |

100 |

20 |

10 |

2 |

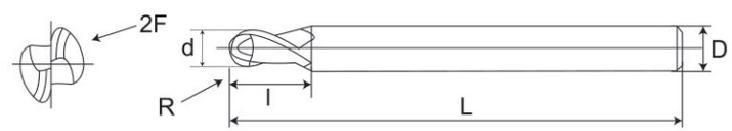

2-Flute Extended Ball End Mill

WC=90/88 Co=10/12 HV30=1571 TRS=3750N/mm² HRC≥91.5 Grain Size=0.6 μm

|

d |

I |

L |

D |

R |

F |

|

4 |

8 |

100 |

4 |

2 |

2 |

|

6 |

12 |

100 |

6 |

3 |

2 |

|

8 |

16 |

100 |

8 |

4 |

2 |

|

10 |

20 |

100 |

10 |

5 |

2 |

|

12 |

25 |

100 |

12 |

6 |

2 |

|

6 |

12 |

150 |

6 |

3 |

2 |

|

8 |

16 |

150 |

8 |

4 |

2 |

|

10 |

20 |

150 |

10 |

5 |

2 |

|

12 |

24 |

150 |

12 |

6 |

2 |

|

14 |

28 |

150 |

14 |

7 |

2 |

|

16 |

32 |

150 |

16 |

8 |

2 |

|

18 |

36 |

150 |

18 |

9 |

2 |

|

20 |

40 |

150 |

20 |

10 |

2 |

Cutting Conditions

|

Processed materials |

Cast iron Ductile iron |

Carbon stee Aalloy steel ~750N/mm2 |

Carbon steel\alloy steel 30HRC |

PHS\QT Steel 40HRC |

Stainless steel |

PHS\QT Steel ~50HRC |

||||||

|

D ( mm) |

RPM (min-¹) |

Federate (mm/min) |

RPM (min-¹) |

Federate (mm/min) |

RPM (min-¹) |

Federate (mm/min) |

RPM (min-¹) |

Federate (mm/min) |

RPM (min-¹) |

Federate (mm/min) |

RPM (min-¹) |

Federate (mm/min) |

|

R0.5 |

40000 |

800 |

40000 |

800 |

38000 |

700 |

32000 |

320 |

22300 |

200 |

25000 |

275 |

|

R1.0 |

24000 |

900 |

24000 |

900 |

19000 |

760 |

16000 |

400 |

11150 |

230 |

13000 |

275 |

|

R1.5 |

15500 |

950 |

15500 |

950 |

2750 |

760 |

10600 |

450 |

7400 |

290 |

8500 |

280 |

|

R2.0 |

11500 |

950 |

11500 |

950 |

9550 |

760 |

8000 |

550 |

5550 |

370 |

6500 |

370 |

|

R2.5 |

9500 |

1050 |

9500 |

1050 |

7650 |

800 |

6400 |

550 |

4450 |

370 |

5000 |

375 |

|

R3.0 |

8000 |

1050 |

8000 |

1050 |

6400 |

800 |

5300 |

580 |

3700 |

390 |

4200 |

390 |

|

R4.0 |

6000 |

1300 |

6000 |

1300 |

4800 |

950 |

4000 |

700 |

2750 |

455 |

3200 |

440 |

|

R5.0 |

4800 |

1200 |

4800 |

1200 |

3800 |

900 |

3200 |

650 |

2200 |

430 |

2500 |

440 |

|

R6.0 |

4000 |

1100 |

4000 |

1100 |

3200 |

840 |

2650 |

610 |

1850 |

430 |

2100 |

420 |

|

R8.0 |

3000 |

1050 |

3000 |

1050 |

2400 |

800 |

2000 |

600 |

1350 |

380 |

1600 |

375 |

|

R10.0 |

2400 |

950 |

2400 |

950 |

1900 |

680 |

1600 |

560 |

1100 |

370 |

1250 |

330 |

|

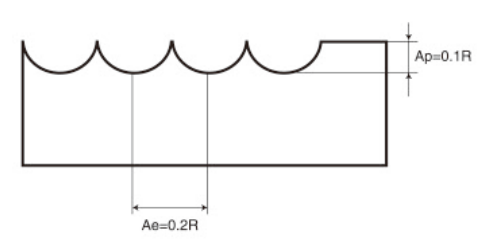

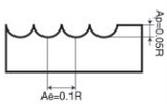

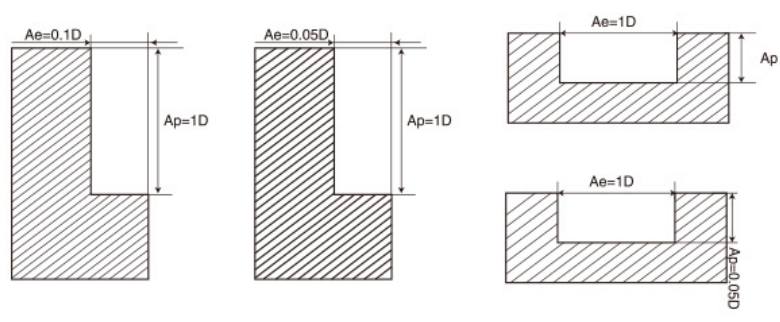

Max Cutting Depth |

|

|

||||||||||

◆Special Attension:

1. This table is the standard value for side milling. When the tool is grooving, the RPM should be 60%~80% of the table below, and the Federate should be 50%~70% as the standard value.

2. Please use high-precision machine tools and tool holders.

3. Please use air cooling or cutting fluid that does not easily produce smoke.

4. Side milling is recommended for down milling.

5. If the rigidity of the machine tool and the workpiece is poor, vibration and abnormal sound will occur. At this time, the RPM and Federate in the table below should be reduced year by year.

6. Keep the tool overhang as short as possible without interference.

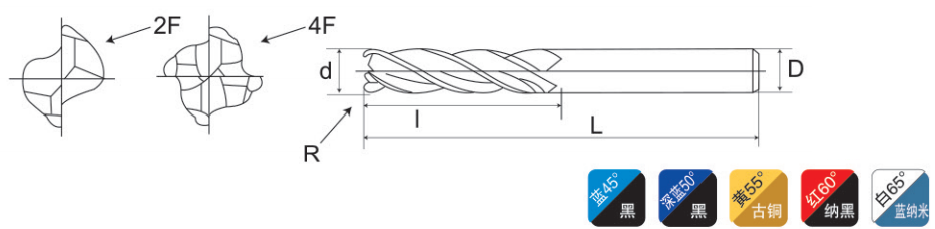

2-Flute/4-Flute Round Nose End Mill

WC=90/88 Co=10/12 HV30=1571 TRS=3750N/mm² HRC≥91.5 Grain Size=0.6μm

2F

|

d |

I |

L |

D |

R |

F |

|

4 |

10 |

50 |

4 |

0.2 |

2/4 |

|

4 |

10 |

50 |

4 |

0.5 |

2/4 |

|

4 |

10 |

50 |

4 |

1 |

2/4 |

|

6 |

15 |

50 |

6 |

0.2 |

2/4 |

|

6 |

15 |

50 |

6 |

0.5 |

2/4 |

|

6 |

15 |

50 |

6 |

1 |

2/4 |

|

8 |

20 |

60 |

6 |

0.2 |

2/4 |

|

8 |

20 |

60 |

8 |

0.5 |

2/4 |

|

8 |

20 |

60 |

8 |

1 |

2/4 |

|

10 |

25 |

75 |

10 |

0.5/1 |

2/4 |

|

10 |

25 |

75 |

10 |

1.5 |

2/4 |

|

12 |

30 |

75 |

12 |

0.5/1 |

2/4 |

|

12 |

30 |

75 |

12 |

1.5 |

2/4 |

|

14 |

35 |

100 |

14 |

0.5/2 |

2/4 |

|

16 |

40 |

100 |

16 |

0.5/1/2 |

2/4 |

|

18 |

45 |

100 |

18 |

0.5/1/2 |

2/4 |

|

20 |

45 |

100 |

20 |

0.5/1/2 |

2/4 |

2-Flute/4-Flute Extend Round Nose End Mill

WC=90/88 Co=10/12 HV30=1571 TRS=3750N/mm² HRC≥91.5 Grain Size=0.6μm

|

d |

I |

L |

D |

R |

F |

|

4 |

16 |

100 |

4 |

0.2 |

2/4 |

|

4 |

16 |

100 |

4 |

0.5 |

2/4 |

|

4 |

16 |

100 |

4 |

1 |

2/4 |

|

6 |

25 |

100 |

6 |

0.2 |

2/4 |

|

6 |

25 |

100 |

6 |

0.5 |

2/4 |

|

6 |

25 |

100 |

6 |

1 |

2/4 |

|

8 |

30 |

100 |

6 |

0.5 |

2/4 |

|

8 |

30 |

100 |

8 |

1 |

2/4 |

|

10 |

40 |

100 |

10 |

0.5 |

2/4 |

|

10 |

40 |

100 |

10 |

1 |

2/4 |

|

12 |

45 |

100 |

12 |

0.5 |

2/4 |

|

12 |

45 |

100 |

12 |

1 |

2/4 |

|

12 |

45 |

100 |

12 |

1.5 |

2/4 |

◆Special Attension:

1. This table is the standard value for side milling. When the tool is grooving, the RPM should be 60%~80% of the table below, and the Federate should be 50%~70% as the standard value.

2. Please use high-precision machine tools and tool holders.

3. Please use air cooling or cutting fluid that does not easily produce smoke.

4. Side milling is recommended for down milling.

5. If the rigidity of the machine tool and the workpiece is poor, vibration and abnormal sound will occur. At this time, the RPM and Federate in the table below should be reduced year by year.

6. Keep the tool overhang as short as possible without interference.

Cutting Conditions

|

2Flute |

||||||||||||||||||||

|

Processed materials |

Cast iron Ductile iron |

Carbon steel Aalloy steel ~750N/mm2 |

Carbon steel Aalloy steel ~30HRC |

PHS\QT Steel ~40HRC |

Stainless steel |

PHS\QT Steel ~50HRC |

||||||||||||||

|

D (mm) |

RPM (min-¹) |

Federate (mm/min) |

RPM (min-¹) |

Federate (mm/min) |

RPM (min-¹) |

Federate (mm/min) |

RPM (min-¹) |

Federate (mm/min ) |

RPM (min-¹) |

Federate (mm/min) |

RPM (min-¹) |

Federate (mm/min) |

||||||||

|

1 |

20000 |

200 |

20000 |

200 |

20000 |

160 |

20000 |

160 |

20000 |

60 |

20000 |

120 |

||||||||

|

2 |

15000 |

320 |

15000 |

320 |

15000 |

290 |

15000 |

280 |

11150 |

84 |

13000 |

180 |

||||||||

|

3 |

14000 |

545 |

14000 |

545 |

13000 |

510 |

10600 |

420 |

7500 |

120 |

8500 |

330 |

||||||||

|

4 |

10800 |

560 |

10800 |

560 |

10000 |

520 |

8000 |

430 |

5500 |

130 |

6500 |

335 |

||||||||

|

5 |

8200 |

580 |

8200 |

580 |

7600 |

540 |

6400 |

450 |

4500 |

130 |

5000 |

355 |

||||||||

|

6 |

7000 |

600 |

7000 |

600 |

6400 |

550 |

5300 |

460 |

3700 |

140 |

4200 |

360 |

||||||||

|

8 |

5200 |

600 |

5200 |

600 |

4800 |

550 |

4000 |

460 |

2800 |

140 |

3200 |

365 |

||||||||

|

10 |

4200 |

580 |

4200 |

580 |

3800 |

540 |

3200 |

445 |

2200 |

140 |

2500 |

350 |

||||||||

|

12 |

3500 |

580 |

3500 |

580 |

3200 |

540 |

2650 |

445 |

1850 |

140 |

2100 |

350 |

||||||||

|

4Flute |

||||||||||||||||||||

|

3 |

14000 |

820 |

14000 |

820 |

13000 |

755 |

10600 |

630 |

7500 |

145 |

8500 |

490 |

||||||||

|

4 |

10800 |

840 |

10800 |

840 |

10000 |

770 |

8000 |

640 |

5500 |

145 |

6500 |

500 |

||||||||

|

5 |

8200 |

880 |

8200 |

880 |

7600 |

810 |

6400 |

670 |

4500 |

145 |

5000 |

530 |

||||||||

|

6 |

7000 |

900 |

7000 |

900 |

6400 |

830 |

5300 |

690 |

3700 |

160 |

4200 |

540 |

||||||||

|

8 |

5200 |

890 |

5200 |

890 |

4800 |

815 |

4000 |

680 |

2800 |

160 |

3200 |

550 |

||||||||

|

10 |

4200 |

880 |

4200 |

880 |

3800 |

810 |

3200 |

670 |

2200 |

160 |

2500 |

520 |

||||||||

|

12 |

3500 |

880 |

3500 |

880 |

3200 |

810 |

2650 |

670 |

1850 |

160 |

2100 |

520 |

||||||||

|

16 |

2600 |

680 |

2600 |

680 |

2400 |

630 |

2000 |

525 |

1400 |

120 |

1600 |

490 |

||||||||

|

Max Cutting Depth

|

|

|||||||||||||||||||

Solid carbide single-Flute straight shank end mill (standard Flute)

Milling cutter applications: stainless steel, cast iron, aluminum, copper, graphite, plastics, composite materials, titanium alloys, nickel, heat-resistant steel, non-alloy steel, low alloy steel <24HRC, high alloy steel

<30HRC、Hardened Steel 30-38HRC 38-48HRC 48-56HRC 56-68HRC

|

Specification |

Specification |

||||||

|

d |

D(h6) |

L1 |

L |

d |

D(h6) |

L1 |

L |

|

3.175 |

3.175 |

12 |

385 |

4 |

4 |

42 |

70 |

|

3.175 |

3.175 |

15 |

38.5 |

6 |

6 |

12 |

50 |

|

3.175 |

3.175 |

17 |

45 |

6 |

6 |

17 |

50 |

|

4 |

4 |

12 |

45 |

6 |

6 |

22 |

50 |

|

4 |

4 |

17 |

45 |

6 |

6 |

25 |

50 |

|

4 |

4 |

22 |

45 |

6 |

6 |

32 |

60 |

|

4 |

4 |

32 |

60 |

6 |

6 |

42 |

70 |

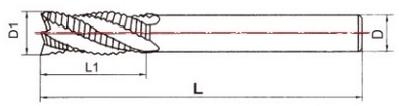

Solid carbide three- or four-flute ball nose end mil

Milling cutter applications: stainless steel, cast iron, aluminum, copper, graphite, plastics, composite materials,

titanium alloy, nickel, heat-resistant steel, non-alloy steel, low alloy steel <24HRC, high alloy steel <30HRC, hardened steel 30-38HRC 38-48HRC 48-56HRC 56-68HRC

|

Specification |

|||

|

D1 |

L1 |

D |

|

|

6 |

15 |

6 |

50 |

|

8 |

20 |

8 |

60 |

|

10 |

25 |

10 |

75 |

|

12 |

30 |

12 |

75 |

|

16 |

40 |

16 |

100 |

|

20 |

45 |

20 |

100 |

INQUIRY

Related product categories

- china flat bottom router bit

- china machining bits

- china tungsten carbide roll rings

- china carbide cnc end mill

- china finished tungsten carbide roller ring

- china reduced shank end mill

- china cemented carbide lathe

- high grinding tungsten carbide

- cnc roughing end mill

- endmill bits

- end mill tool

- cemented carbide blank

EN

EN UR

UR ru

ru bn

bn ar

ar ky

ky th

th fil

fil vi

vi ms

ms tr

tr ro

ro pt

pt es

es af

af fa

fa uk

uk nl

nl pl

pl fr

fr de

de