Description

|

Rang of O.D. |

Rang of I.D. |

Rang of height |

|

145-330 |

87-260 |

45-130 |

Tolerances allowable for the O.D.I.D.and height of roll rings

|

Precision class |

1 |

2 |

3 |

4 |

Special requirements |

|

O.D. (±) |

0.02 |

0.05 |

0.10 |

0.15 |

|

|

0.D. (±) |

IT 5 |

IT6 |

IT7 |

IT8 |

|

|

Height(-) |

0.03 |

0.1 |

0.20 |

0.5 |

The allwable deviation of carbide roll rings

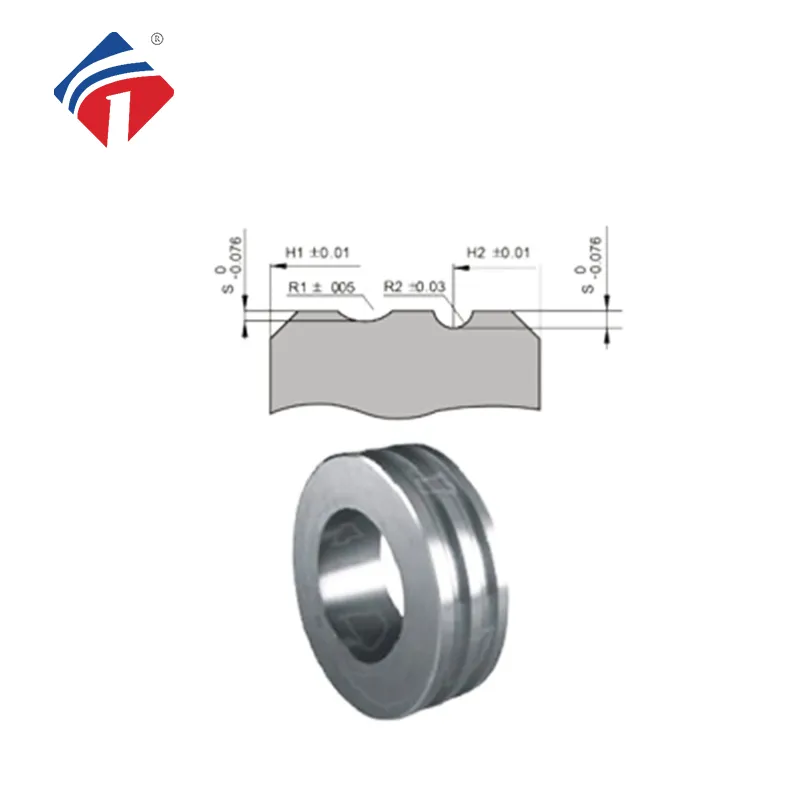

Radial runout of groove≤0.013mm

Radial runout of geriphery≤0.013mm

End face runout≤0.02mm

End face planeness≤0.01mm

End face parallelism≤0.01mm

Inner hole cylindericity≤0.01m

Roughness of carbide rolls

Inner hole roughness 0.4μm Periphery roughness 0.4μm

End face roughness 0.4μm

The allowable deviation in external diameter, diameter and height is to be determined based on customers’need.

Note:Wecan supply them according to the drawings provided by customers

For more related materials, please download

① The table of specifiations of the finished carbide roll blanks

② Recommended applications of grades for carbide roll rings

③ Table of grades and properties of carbide roll rings and related data

④ Operational requirements of cemented carbide roll rings

EN

EN UR

UR ru

ru bn

bn ar

ar ky

ky th

th fil

fil vi

vi ms

ms tr

tr ro

ro pt

pt es

es af

af fa

fa uk

uk nl

nl pl

pl fr

fr de

de