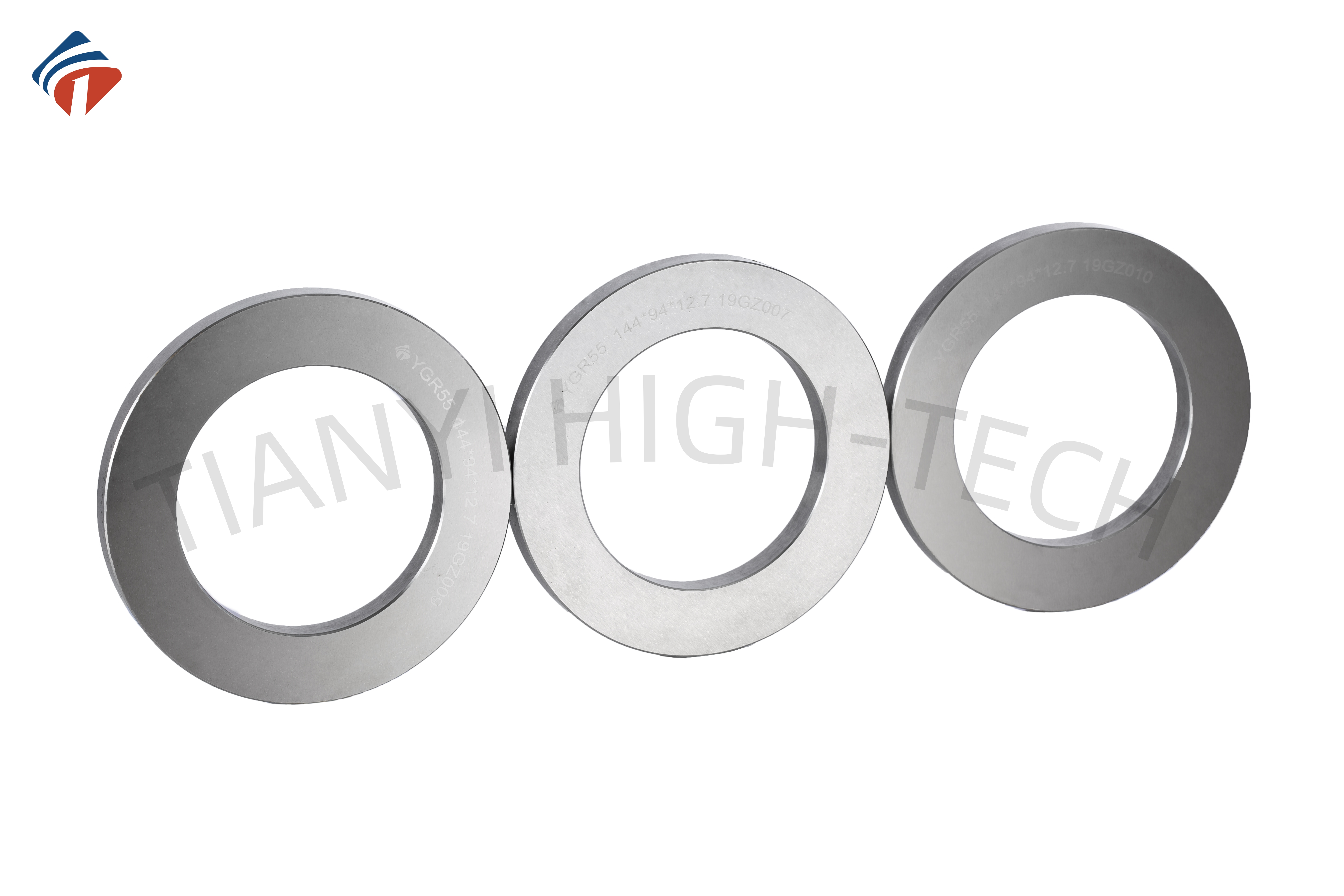

Cold-rolled Three Dimensional Carbide Roller Rings

Product Information

- Material: WC, Metallic binder (Cobalt, Nickel, etc.)

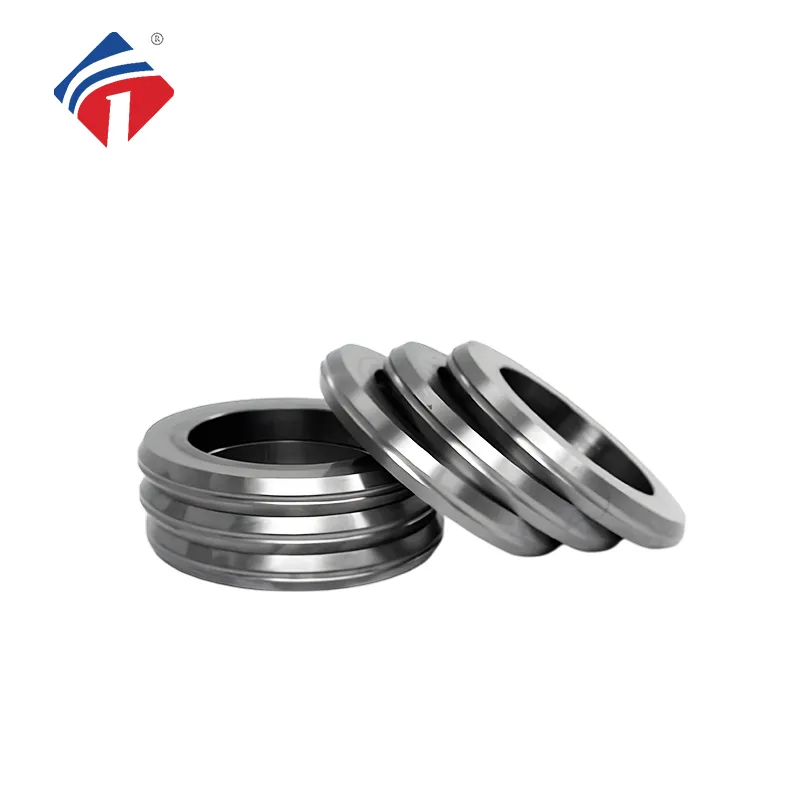

- Roller Style: Grooving roller.

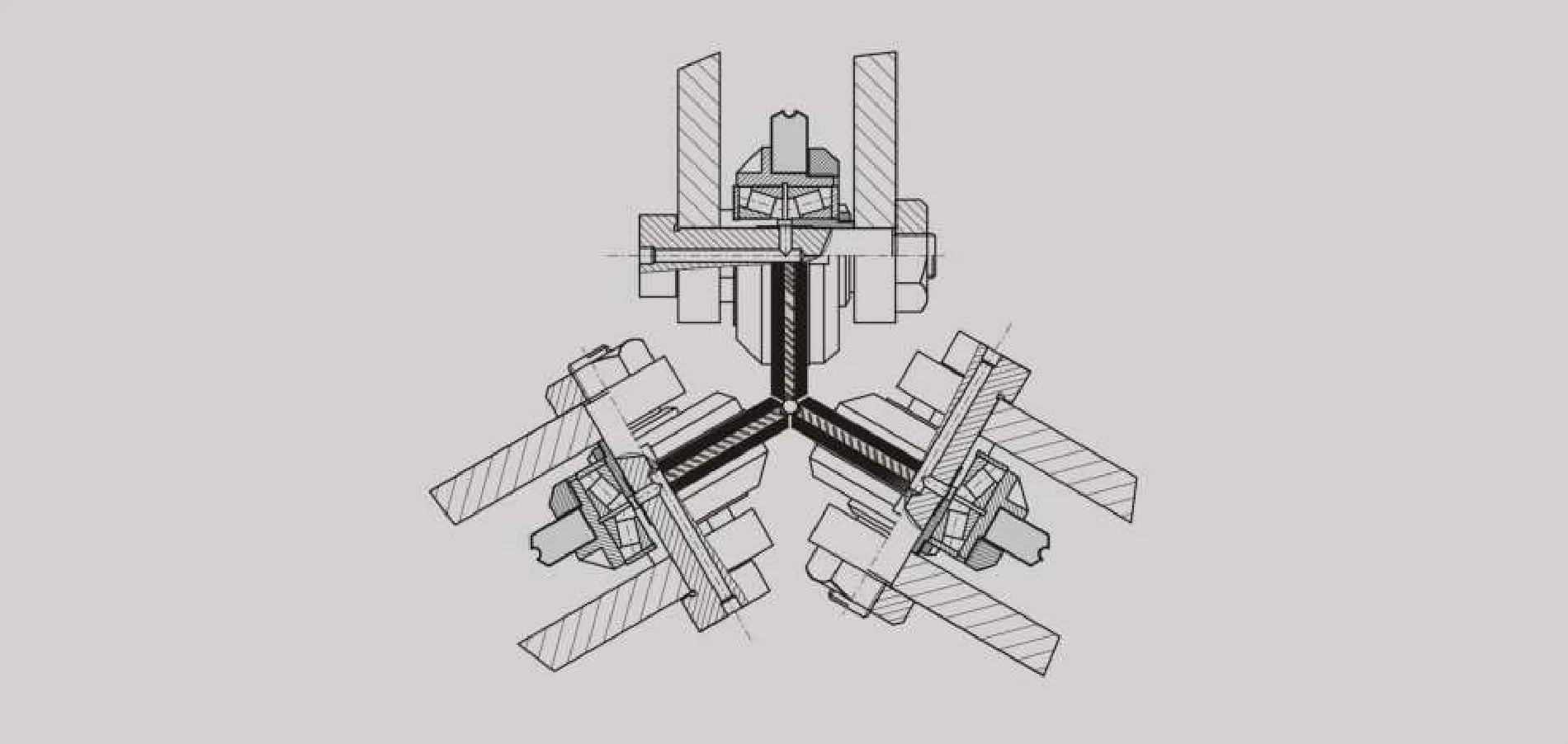

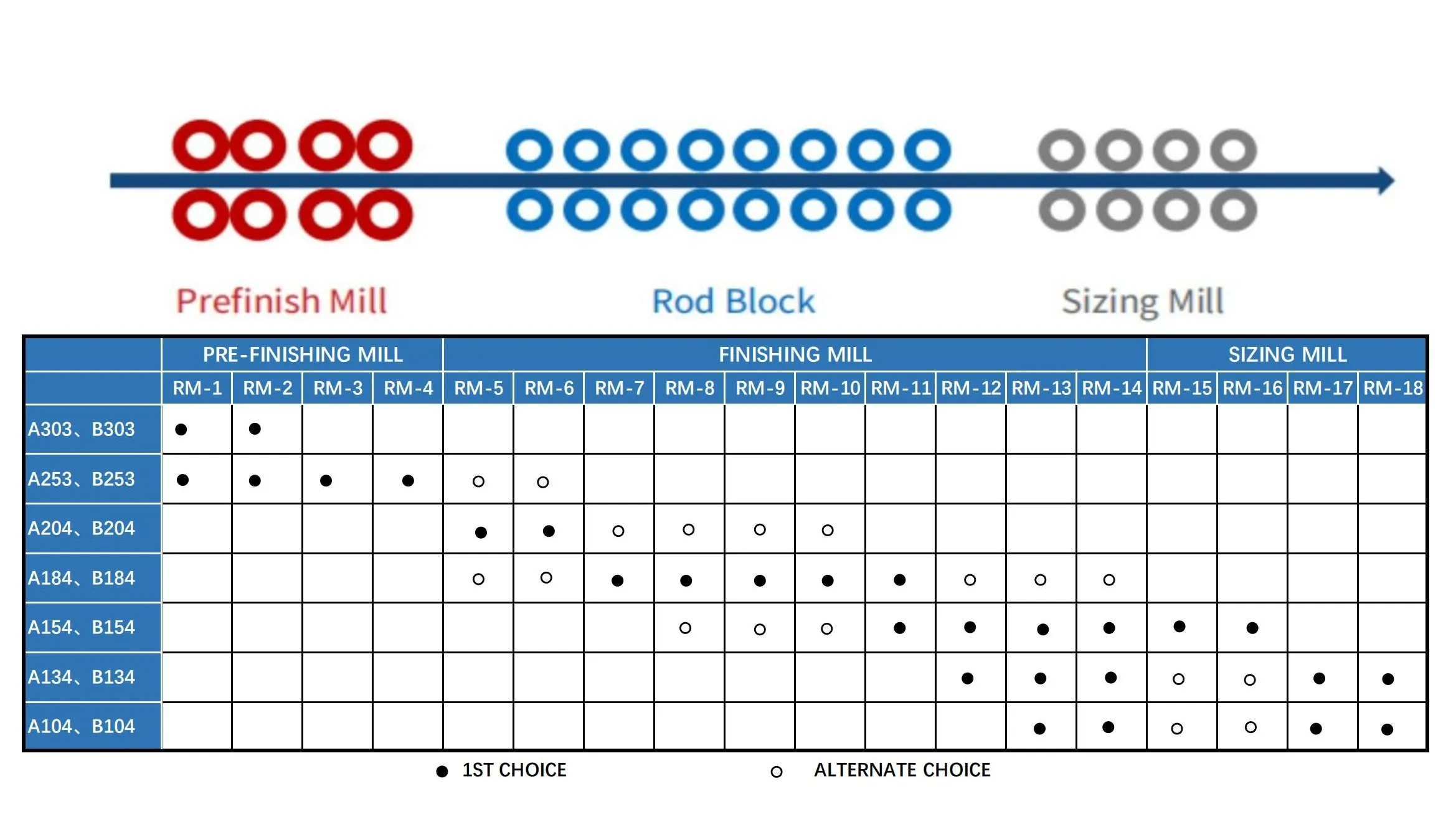

- Rolling Mill: Pre-finishing Mill & Finishing Mill & Reducing Mill.

- Types of Rolling: Cold Rolling(Room temperature)

- Surface: Polishing.

- Advantage: exceptional hardness, high wear resistance, and durability

- Certification: ISO Certificate.

- Other Services: OEM/ODM.

Description

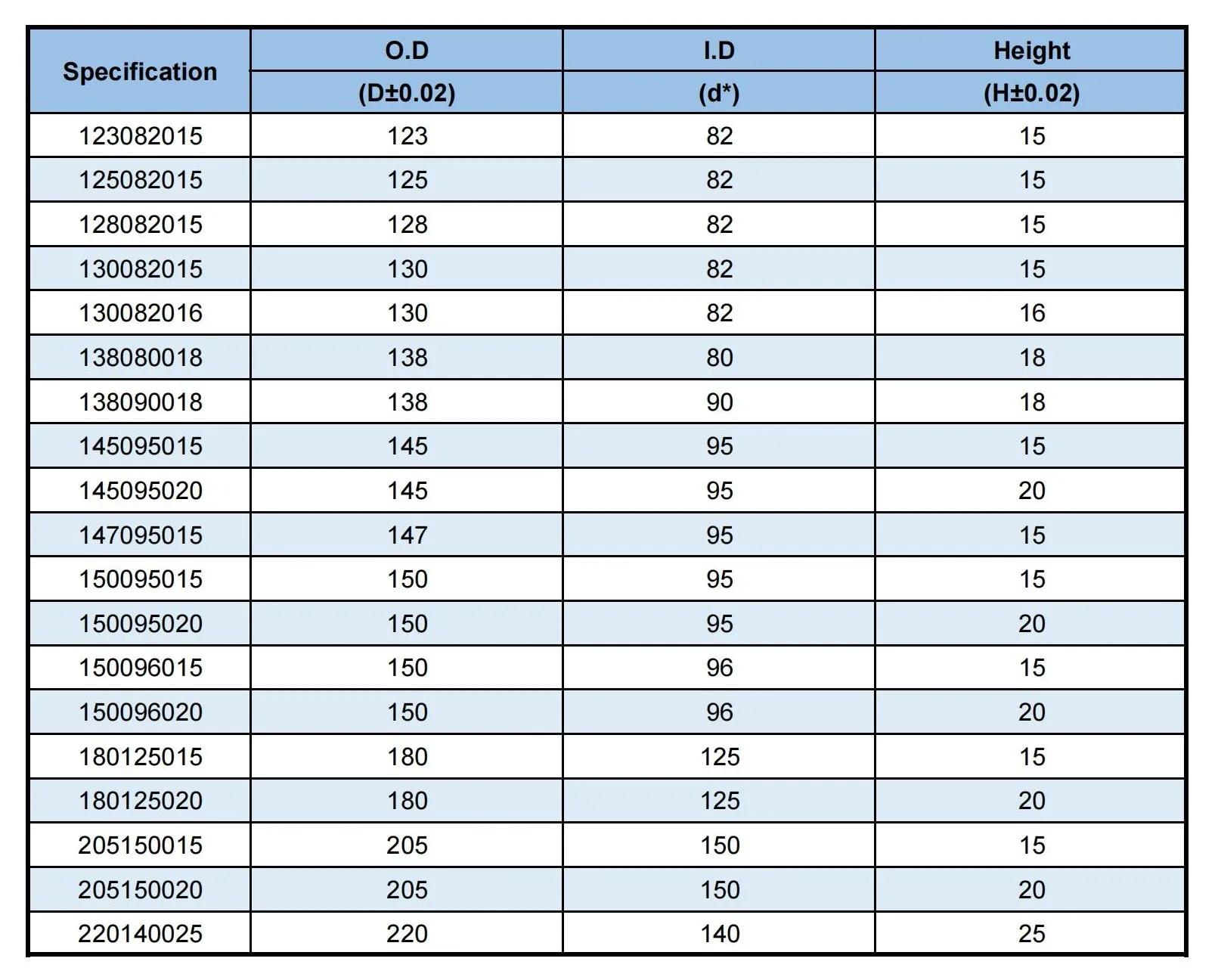

Technical Parameter

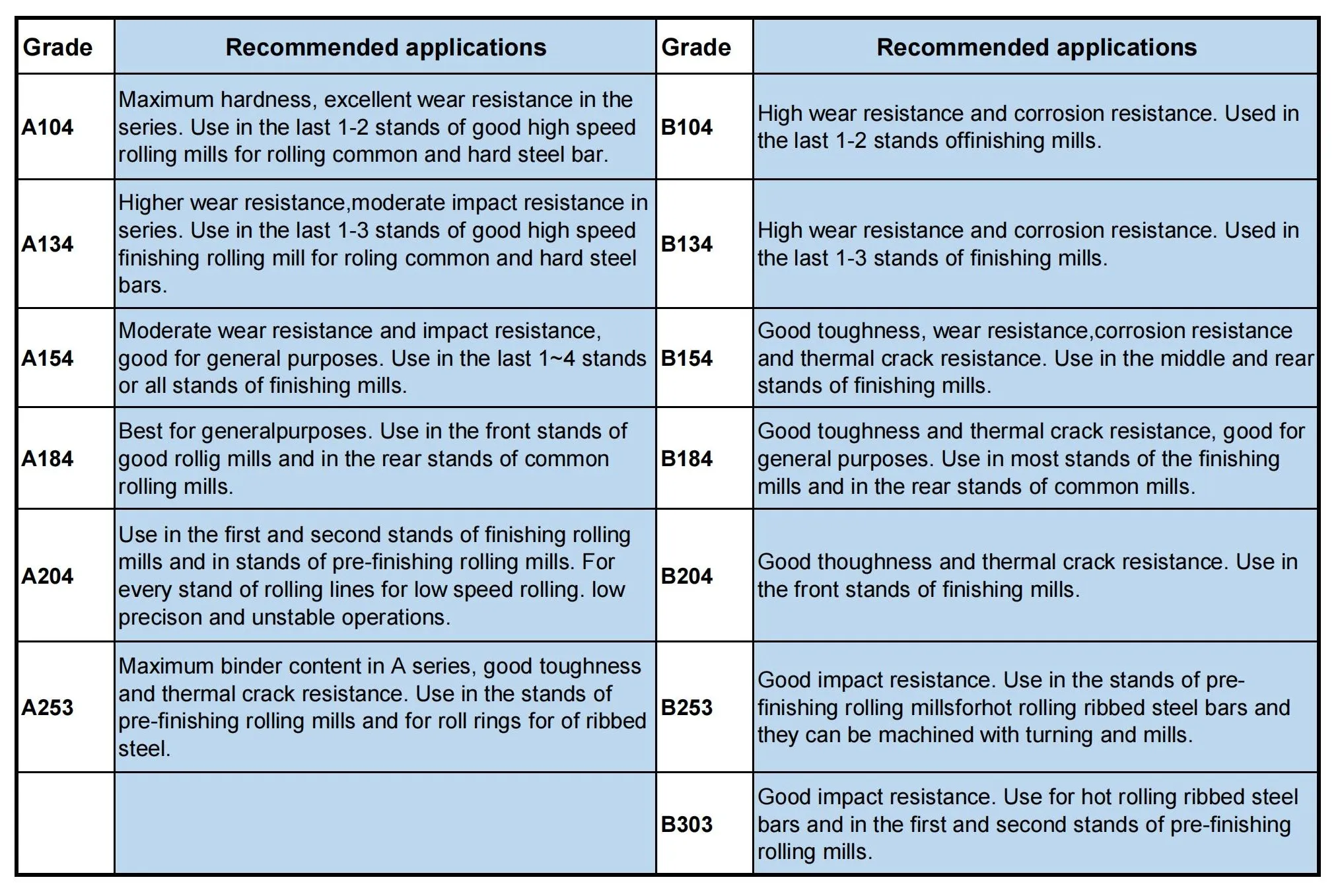

Cemented carbide roll rings (also known as Tungsten Carbide Roll Rings) offer excellent thermal conductivity and outperform first-generation cast-iron and high-speed-steel rolls in heat resistance, wear resistance, and strength, with minimal hardness reduction at high temperatures. Developed alongside high-speed wire rod mills, they are now extensively applied in the finishing stands for manufacturing high-speed wire, rebar, and deformed steel bars.

| Grade | Chemical Composition | Mechanical Properties | Recommended Application | |||

| WC% | CO% | Density (g/cm³) | Hardness (HRA) | Transverse rupture strength (Sample B) Mpa |

||

| A154 | 85% | 15% | 13.8~14.2 | 83.5 | 2520 | Cold Rolling Ribbed Steel |

| YG15 | 85% | 15% | 13.9~14.2 | 86.5 | 2220 | |

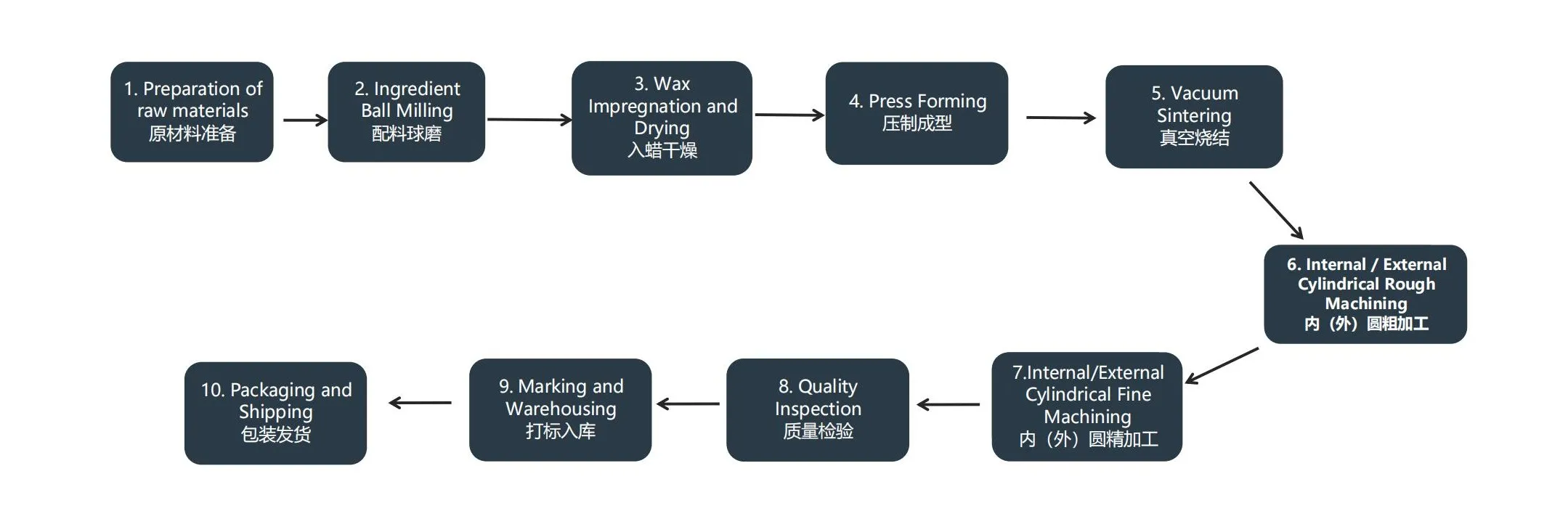

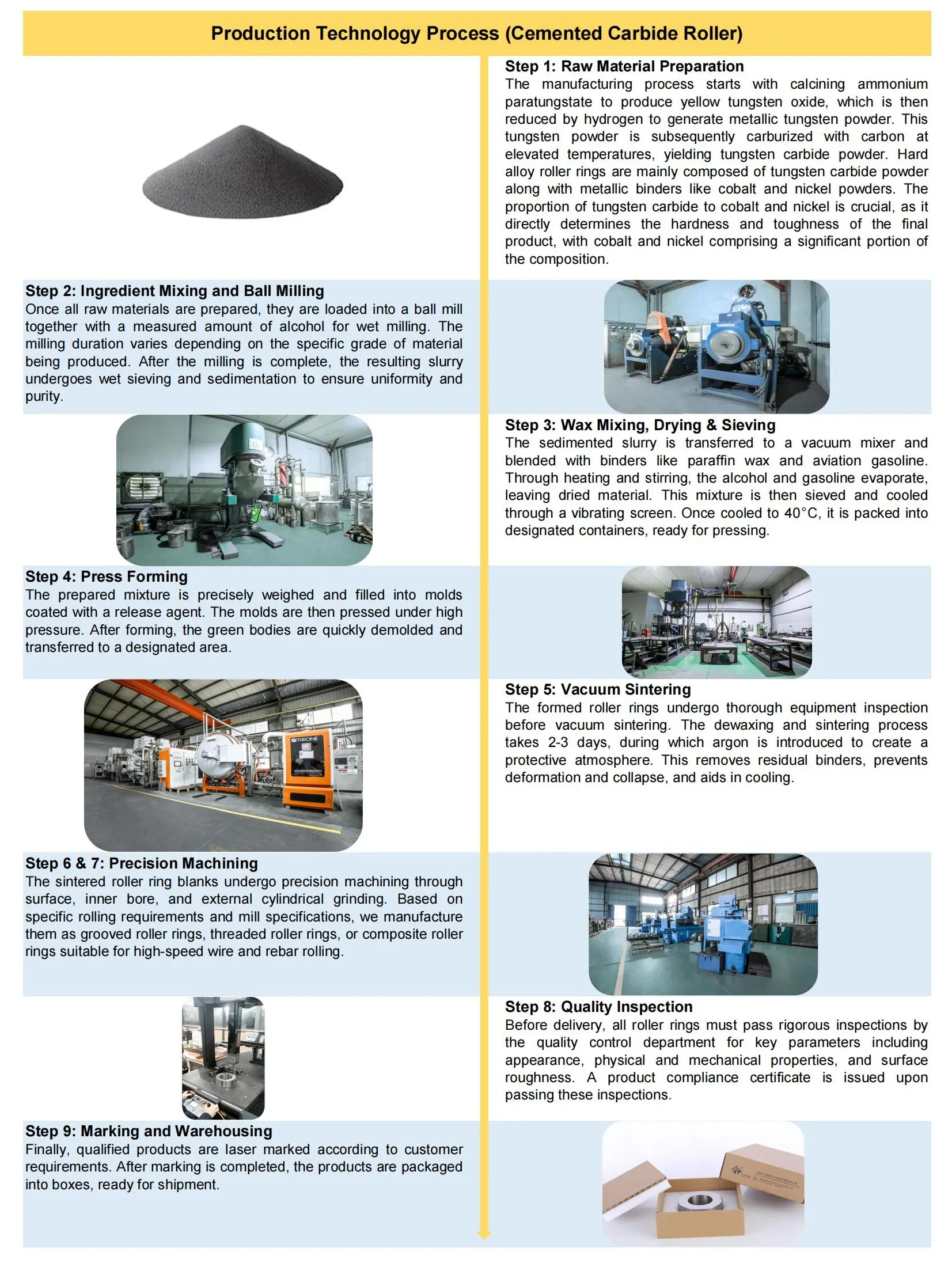

Production Technology Process

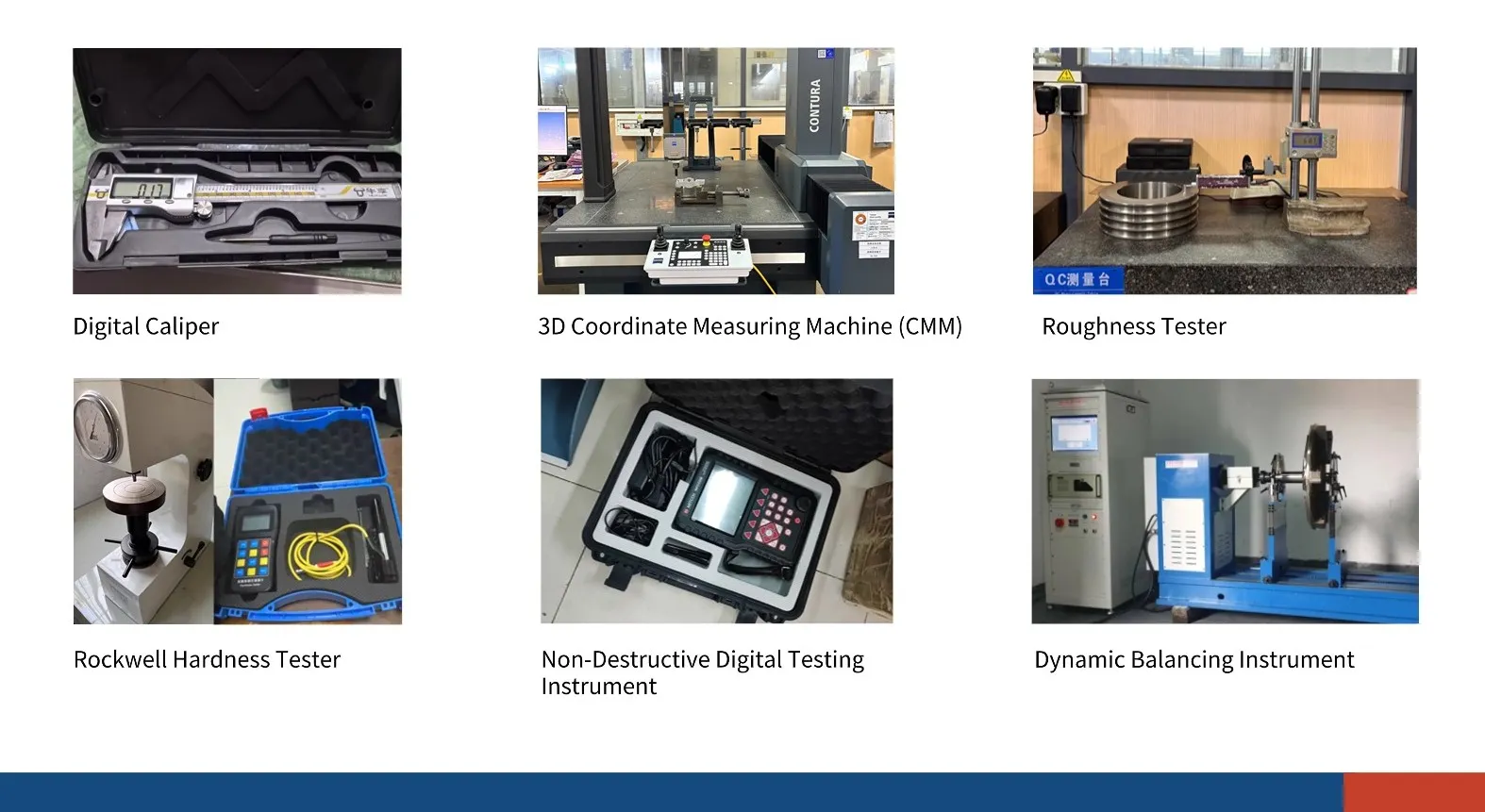

Quality Inspection Equipment

INQUIRY

Related product categories

- rolls for roll rings

- carbide roll rings with tight tolerances for bar mills

- OEM carbide roll rings for steel mills

- roller rings compatible with SMS Group for wire rod mills

- durable carbide roll rings for hot strip mills

- roller rings compatible with SMS Group for pilger mills

- custom-manufactured roll rings Italy

- carbide roll rings with tight tolerances Italy

- wholesale carbide roll rings Russia

- cemented carbide burr blank

- cemented alloy bar blanks

- cemented carbide roller

EN

EN UR

UR ru

ru bn

bn ar

ar ky

ky th

th fil

fil vi

vi ms

ms tr

tr ro

ro pt

pt es

es af

af fa

fa uk

uk nl

nl pl

pl fr

fr de

de