Advancements in Corning ColdForm™ Cold Bending Technology and Microcrystalline Glass Processing

Corning’s ColdForm™ technology is a patented innovation designed to bend glass without the need for heating, offering significant cost and energy savings compared to traditional hot bending methods.

Is Corning's Cold Bending Technology Applicable to All Types of Glass?

The answer is No. This technology is primarily suitable for tempered glass, particularly targeting Corning’s Gorilla Glass, known for its thinness, flexibility, and durability. However, cold bending may not be suitable for ordinary or more fragile types of glass.

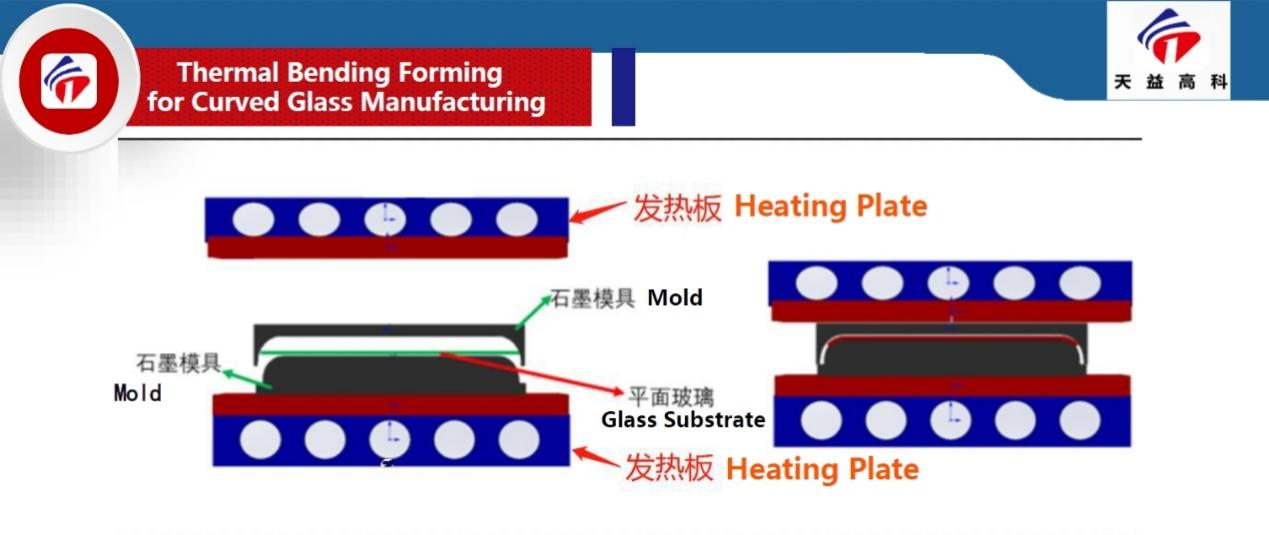

For instance, microcrystalline glass, valued for its superior optical and mechanical properties, is widely used in 3C products such as smartphones, smartwatches, tablets, and other screen covers. Due to its high strength and toughness, microcrystalline glass requires hot bending temperatures of up to 900°C, making traditional 310S heating plates unsuitable for processing.

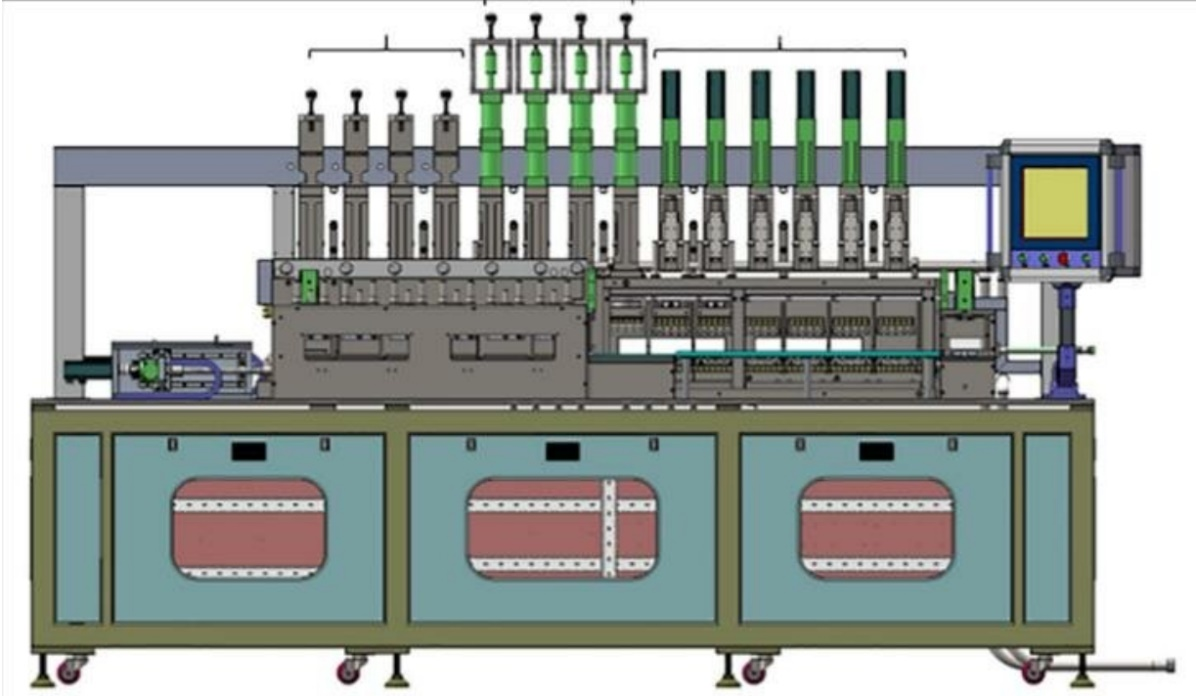

To address this challenge, Tianyi High-Tech has developed a superalloy composite metal heating plate with high resistance to oxidation, strength at high temperatures, and excellent thermal conductivity. This new heating plate is compatible with 3D glass bending machines, non-spherical glass precision press machines, and automotive curved glass bending machines, greatly improving both the production yield and forming accuracy of glass.

Related product categories

- carbide roll ring maintenance for finishing stands

- cemented carbide rolls for pilger mills

- corrosion-resistant carbide rolls for hot rolling

- tungsten carbide rolls Vietnam for pilger mills

- cemented carbide roll rings for bar mills

- carbide rolls for cold rolling

- OEM carbide roll rings Japan

- cemented carbide insert for roughing

- cemented carbide tool bits for deburring

- end mill cutters

- cemented carbide friction dril

- china solid carbide rods

EN

EN UR

UR ru

ru bn

bn ar

ar ky

ky th

th fil

fil vi

vi ms

ms tr

tr ro

ro pt

pt es

es af

af fa

fa uk

uk nl

nl pl

pl fr

fr de

de