Main Characteristics of Cemented Carbide

Cemented carbide occupies an important position in the metal forming, plastic injection molding, glass manufacturing and wire drawing industries due to its excellent durability, precision and versatility. The quality of cemented carbide directly affects production efficiency and service life. The three main characteristics of cemented carbide are as follows:

1. Density of cemented carbide

The density of cemented carbide ranges widely, from about 5.5g/cm³ for TiC-based alloys to about 15.4g/cm³ for low-cobalt WC-based alloys. Sintered cemented carbide usually has some residual porosity, so the measured density value is slightly lower than the theoretical value. For tungsten-cobalt cemented carbide, its density depends first on the cobalt content. The higher the cobalt content, the lower the density. In addition, graphite inclusions, pores and foreign impurities will slightly reduce the density of the alloy, while the large presence of η phase in the alloy will cause a slight increase in density. When the η phase is serious, its density may exceed the theoretical value.

For titanium-tungsten-cobalt alloys, its density is closely related to the content of titanium carbide and cobalt. As the content of titanium carbide or cobalt increases, the density of the alloy decreases.

2. Hardness of cemented carbide

Due to the large amount of hard carbides in cemented carbide, its hardness is much higher than that of high-speed steel. The hardness of YG cemented carbide for cutting is generally HRA88~93, and the hardness of YT cemented carbide is HRA89~94. The higher the content of binder cobalt in cemented carbide (the lower the content of hard phase carbides), the lower the hardness of the alloy.

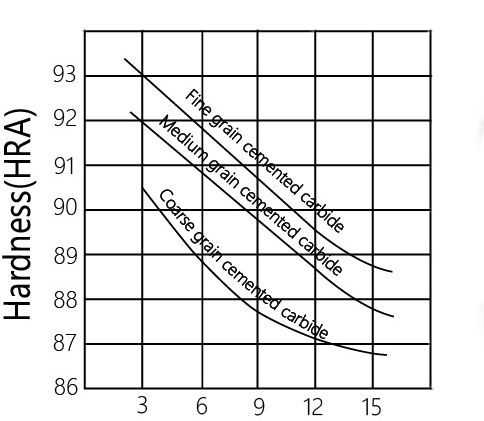

Relationship between WC-Co alloy hardness, cobalt content and tungsten carbide grain size

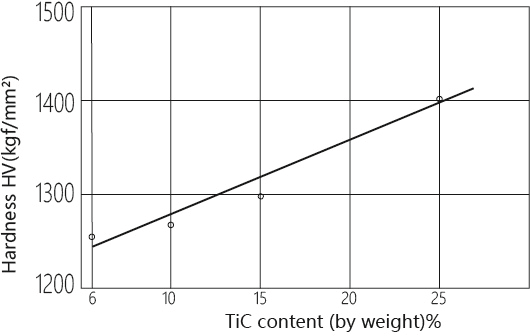

Relationship between hardness and TiC content of WC-TiC-Co alloy containing Co9%

3. Bending strength σbb

The tool is usually subjected to bending stress during cutting, so the bending strength is generally used to represent the strength characteristics of cemented carbide. The bending strength of coarse-grained cemented carbide is much lower than that of high-speed steel. Even the higher-strength YG8 alloy (σbb=1500MPa) has a bending strength of only about half that of W18Cr4V high-speed steel. However, the bending strength of fine-grained cemented carbide is higher than that of high-speed steel, but it has no significant ductility, so it exhibits a collapse phenomenon.

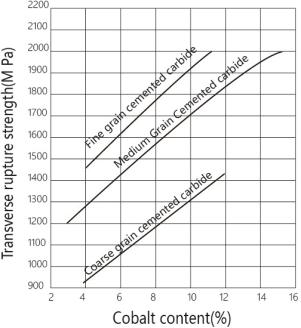

Relationship between flexural strength of cemented carbide and cobalt content

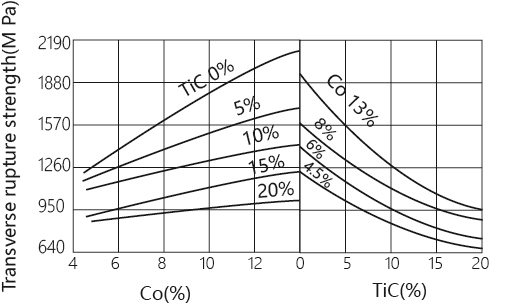

Influence of TiC and Co Contents on Flexural Strength of WC-TiC-Co Alloy

Related product categories

- China heat-resistant roller rings

- long-lasting carbide roll rings for high-speed wire rod mills

- carbide rolls for seamless tube mills

- benefits of using cemented carbide roll rings for alloy steel rolling

- long-life roller rings for dable carbide roll rings

- best carbide roll rings for section mills

- cemented carbide roller manufactuer for finishing

- carbide roll collar for wood cutting

- cemented carbide inserts for engraving

- china cnc end mills aluminum

- solid carbide end mills

- cemented carbide cutter

EN

EN UR

UR ru

ru bn

bn ar

ar ky

ky th

th fil

fil vi

vi ms

ms tr

tr ro

ro pt

pt es

es af

af fa

fa uk

uk nl

nl pl

pl fr

fr de

de